How to Select the Right Industrial Water Pump for Your Specific Application Needs

In the rapidly evolving industrial sector, the selection of the right industrial water pump is crucial for optimizing operational efficiency and reducing costs. According to a recent report by MarketsandMarkets, the global industrial pump market is expected to reach $81.3 billion by 2025, driven by the growing demand for efficient fluid management solutions across various industries.

However, the effectiveness of these systems largely depends on choosing the right pump type and specifications to meet specific application needs. Factors such as flow rate, pressure requirements, and fluid characteristics must be carefully evaluated to ensure maximum performance and longevity of the pump. With the increasing complexity of industrial processes, a well-informed selection is not just beneficial but essential for maintaining competitive advantage and enhancing productivity.

This guide will elucidate the key considerations for selecting the appropriate industrial water pump tailored to unique application demands.

Understanding Your Application Requirements for Industrial Water Pumps

When selecting the right industrial water pump, understanding your application requirements is crucial. Different applications demand varying flow rates, pressure, and fluid characteristics. For instance, according to the Hydraulic Institute's 2021 report, industries such as wastewater treatment often require pumps with a flow rate exceeding 1,000 gallons per minute (GPM) and the capability to handle solids-laden fluids. In contrast, processes in food and beverage production may necessitate sanitary pumps that conform to FDA standards, emphasizing the need for materials resistant to corrosion and easy to clean.

Moreover, the energy efficiency of the pump is a critical factor to consider. A study by the U.S. Department of Energy indicated that pumps account for approximately 20% of industrial energy use, highlighting the importance of selecting pumps that not only meet application needs but also optimize energy consumption. Variable frequency drives (VFDs) and multi-stage pumps can also enhance energy efficiency by adjusting the pump’s performance based on real-time demands. Therefore, aligning your specific industrial requirements with the right pump features will ultimately result in enhanced performance and reduced operational costs.

Evaluating Different Types of Industrial Water Pumps Available

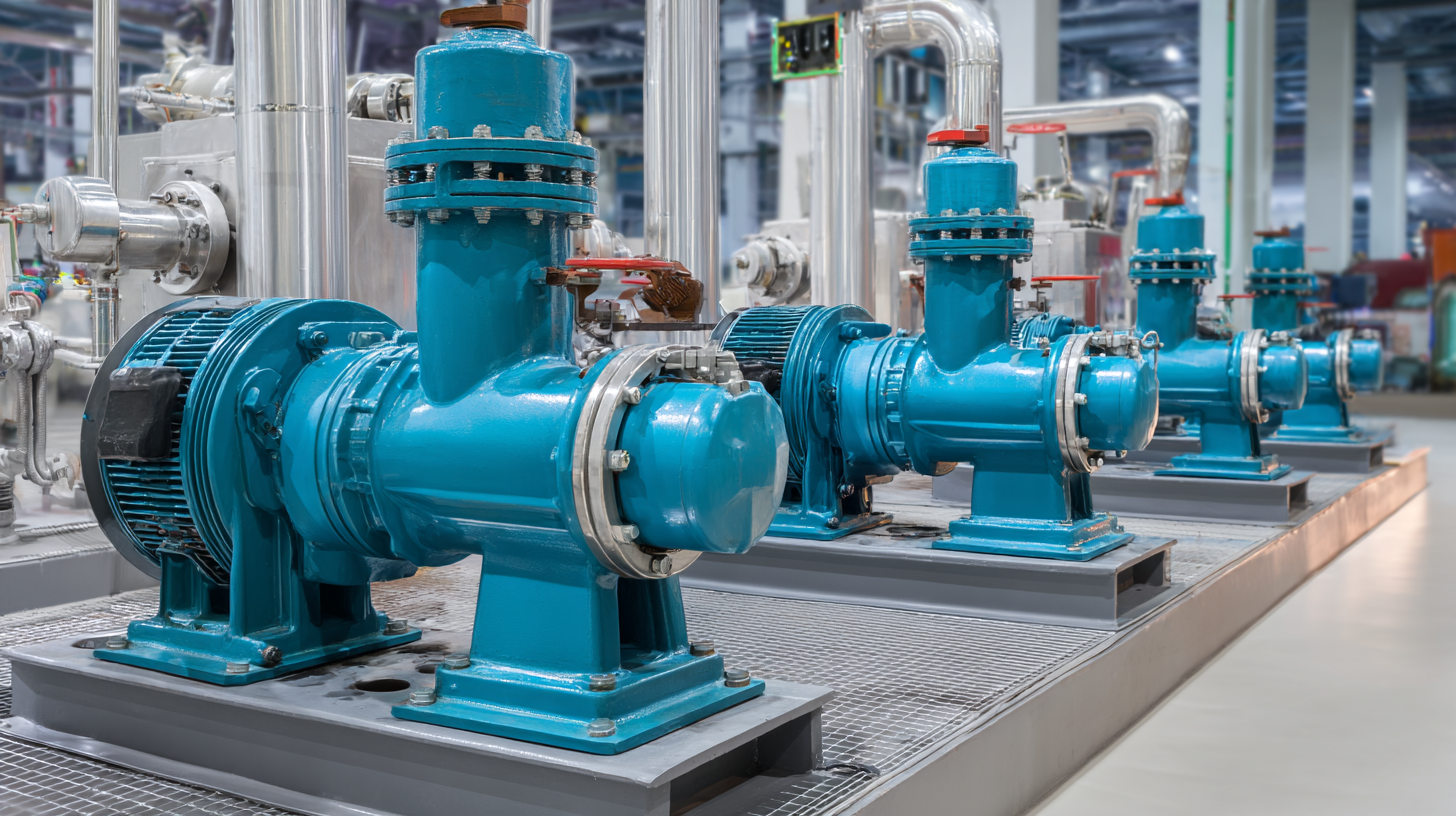

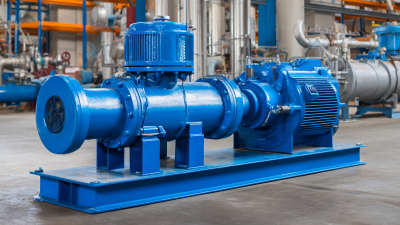

When evaluating different types of industrial water pumps, it is essential to understand the specific requirements of your application to ensure optimal performance and efficiency. Common types include centrifugal pumps, positive displacement pumps, submersible pumps, and diaphragm pumps, each designed for distinct operating conditions and media. Centrifugal pumps are widely used for their ability to handle large volumes of water at relatively low pressures, making them suitable for applications like irrigation and water treatment. In contrast, positive displacement pumps are ideal for applications requiring high pressure and consistent flow rates, making them effective for transferring viscous fluids or handling slurries.

Moreover, submersible pumps are employed in situations where pumping is needed below the surface, such as in wells or sewage systems, while diaphragm pumps excel in applications demanding the handling of corrosive liquids or slurries without leakage. It’s critical to consider factors such as the pump's material, size, energy efficiency, and maintenance needs when selecting the right pump for your application. By carefully assessing each pump type's characteristics against your specific operational demands, you can ensure that you choose an industrial water pump that maximally meets your goals.

How to Select the Right Industrial Water Pump for Your Specific Application Needs

| Pump Type | Flow Rate (GPM) | Head (Feet) | Power Source | Common Applications |

|---|---|---|---|---|

| Centrifugal Pump | 10 - 1200 | 10 - 150 | Electric, Diesel | Water supply, Agriculture |

| Submersible Pump | 5 - 2000 | 10 - 200 | Electric | Sewage, Flood control |

| Diaphragm Pump | 1 - 100 | 5 - 50 | Air, Electric | Chemical transfer, Water treatment |

| Gear Pump | 0.5 - 200 | 10 - 100 | Electric, Hydraulic | Lubrication, Fuel transfer |

| Peristaltic Pump | 0.1 - 130 | 5 - 50 | Electric | Pharmaceuticals, Food processing |

Key Factors to Consider When Choosing Water Pump Specifications

When selecting the right industrial water pump, it is crucial to consider several key factors that align with your specific application needs. First and foremost, flow rate and pressure requirements must be evaluated. Understanding the volume of water needed and the height to which it needs to be pumped will guide you in choosing a pump that is not only efficient but also capable of performing optimally under the expected conditions. Choosing a pump that meets these specifications ensures reliability and reduces the risk of operational downtime.

Another important factor is the type of liquid being pumped. Different applications may involve clean water, slurries, or corrosive fluids, each requiring pumps constructed from appropriate materials. Additionally, considering the pump’s installation environment plays a significant role; for instance, if the pump will be exposed to extreme temperatures or corrosive environments, selecting a pump with the right protective features and coatings can enhance durability and performance. These factors combined will help in identifying a pump that fits both operational needs and longevity goals.

Assessing Pump Performance and Efficiency for Your Needs

When selecting an industrial water pump, assessing pump performance and efficiency is crucial to meet specific application needs. The performance of a pump is typically quantified by its flow rate, pressure, and overall head. Understanding the required flow rate for your application is essential, as insufficient flow can lead to system inefficiencies and increased operational costs. Therefore, it is important to consider both the maximum and average flow rates during the selection process to ensure the pump can handle varying demands.

Efficiency is another key factor in pump selection. A more efficient pump consumes less energy for the same output, reducing operational expenses over time. It's important to evaluate the pump's operation curve, which illustrates the relationship between flow rate and total dynamic head. Selecting a pump that operates near its best efficiency point (BEP) can significantly enhance system performance and lower the chances of premature wear. Investing time in assessing these aspects will lead to a well-informed decision, optimizing both performance and energy consumption for your specific industrial application.

Industrial Water Pump Efficiency Comparison

This chart illustrates the efficiency of various types of industrial water pumps based on their flow rate (GPM) and power consumption (HP). A higher efficiency indicates better performance for specific applications, making it crucial to select the right pump type for your needs.

Ensuring Compatibility with Existing Systems and Infrastructure

When selecting the right industrial water pump, ensuring compatibility with existing systems and infrastructure is crucial. This process begins with a thorough assessment of the current system’s specifications, such as flow rate, pressure requirements, and the physical layout of pipework. Understanding these parameters allows for the selection of a pump that can easily integrate into the existing framework without significant modifications or upgrades.

When selecting the right industrial water pump, ensuring compatibility with existing systems and infrastructure is crucial. This process begins with a thorough assessment of the current system’s specifications, such as flow rate, pressure requirements, and the physical layout of pipework. Understanding these parameters allows for the selection of a pump that can easily integrate into the existing framework without significant modifications or upgrades.

Moreover, it is essential to consider the type of fluids being pumped and their characteristics. Different materials and pump designs are suited for specific applications, such as corrosive liquids or those with solids. Ensuring that the new pump can handle the particular demands of the existing setup prevents issues like premature wear or system failures. Additionally, communication with pump manufacturers can provide valuable insights into the best options that fit both performance needs and existing infrastructure, ultimately leading to a seamless integration and efficient operation.

Related Posts

-

Ultimate Guide to Choosing the Best 12 Volt Sprayer Pump for Your Agricultural Needs

-

Exploring Innovative Alternatives to Chemical Pumps for Enhanced Efficiency and Reliability

-

How to Choose the Best Pressure Pump for Water Efficiency Based on Industry Standards

-

Comprehensive Guide to Choosing the Right High Pressure Diaphragm Pump for Your Needs

-

7 Essential Tips for Choosing the Best Electric Water Pump for Your Needs

-

5 Smart Tips to Choose the Best Small Electric Water Pump