Revolutionizing Fluid Handling: The Essential Guide to Electric Transfer Pumps for Every Need

In today's rapidly evolving industrial landscape, the efficiency and effectiveness of fluid handling are paramount. One of the most significant advancements in this field is the electrification of transfer pumps, notably the electric transfer pump. This guide aims to delve into the various types of electric transfer pumps available, exploring their applications, benefits, and optimal use across different industries. Whether you are managing a construction site, agricultural operation, or any setting that requires the movement of liquids, understanding the nuances of electric transfer pumps will empower you to make informed decisions. This “how to” guide is designed to provide comprehensive insights into selecting the right pump for your specific needs, ensuring that you not only enhance productivity but also maintain safety and sustainability in your operations. Join us as we explore the revolutionary impact of electric transfer pumps on fluid handling processes.

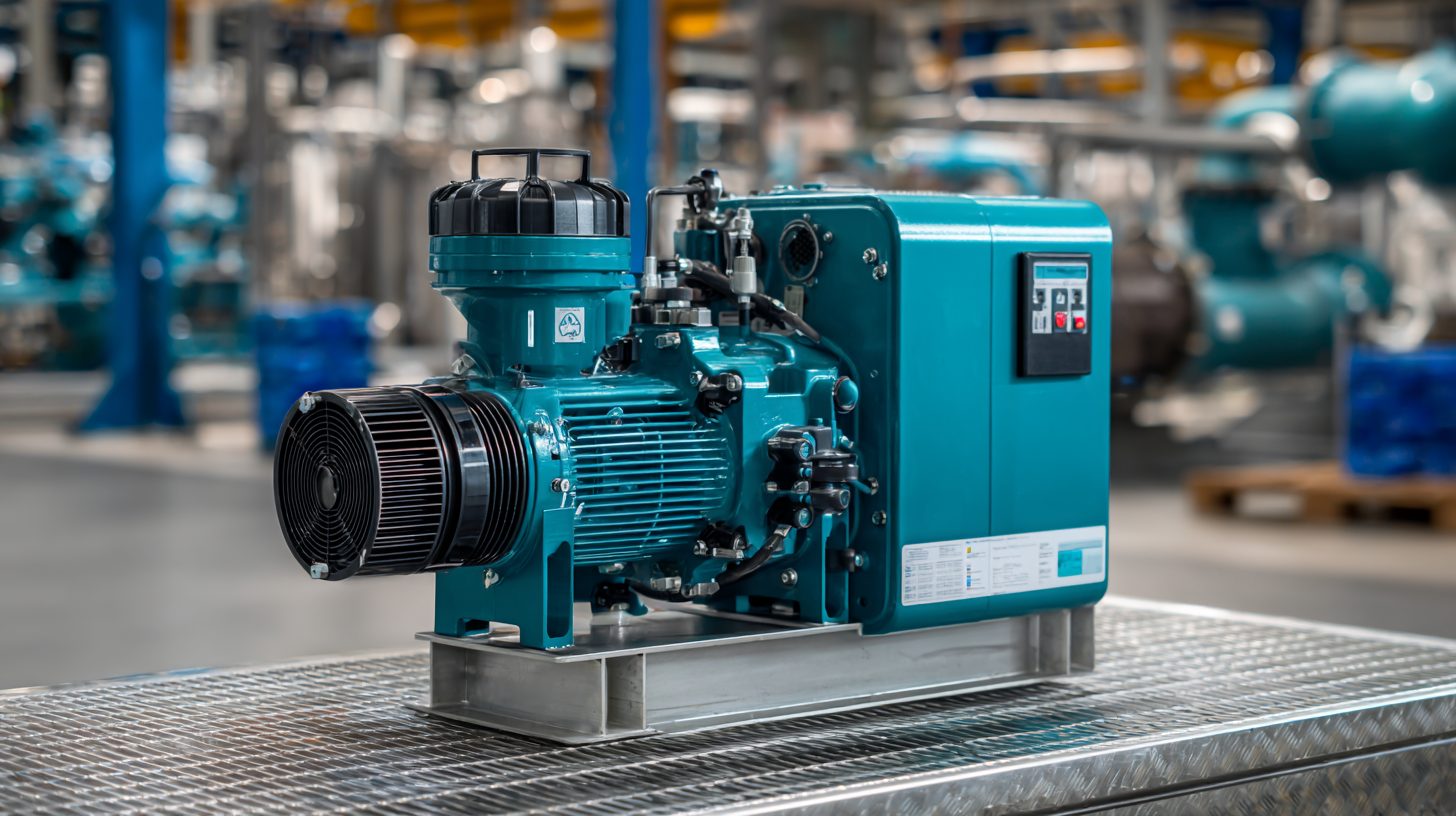

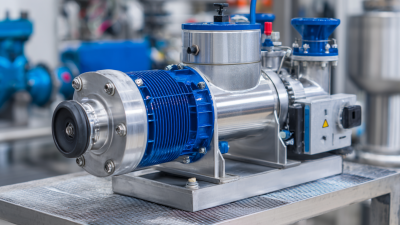

Understanding the Different Types of Electric Transfer Pumps and Their Applications

Electric transfer pumps are a vital component in various industries due to their efficiency and versatility in handling fluids. Understanding the different types available is essential for selecting the right pump for specific applications. The primary categories include centrifugal pumps, diaphragm pumps, and peristaltic pumps, each designed to meet unique operational requirements. According to a report by Grand View Research, the global electric pump market is expected to reach $55.52 billion by 2027, driven by the growing demand for industrial automation and advanced fluid management systems.

Centrifugal pumps are widely used for transferring clean water and other low-viscosity fluids in agricultural and municipal settings. Their design allows for high flow rates with minimal energy consumption, making them ideal for applications requiring constant flow. Diaphragm pumps, on the other hand, are preferred for handling corrosive or viscous fluids, ensuring precise flow control and leak-free operation. Data from Research and Markets indicates that the diaphragm pump segment will witness significant growth, with an expected CAGR of 7.3% from 2020 to 2027, highlighting the increasing need for specialized fluid handling solutions across industries. Each pump type plays a crucial role in optimizing processes, reducing costs, and enhancing safety in fluid-handling applications.

Revolutionizing Fluid Handling: The Essential Guide to Electric Transfer Pumps for Every Need

| Pump Type | Power Source | Flow Rate (L/min) | Max Pressure (bar) | Common Applications |

|---|---|---|---|---|

| Submersible Pump | Electric | 30 | 3.5 | Water extraction, sewage handling |

| Centrifugal Pump | Electric | 100 | 6 | Irrigation, HVAC systems |

| Diaphragm Pump | Electric | 25 | 4 | Chemical transfer, medical applications |

| Gear Pump | Electric | 50 | 8 | Oil transfer, lubrication systems |

| Peristaltic Pump | Electric | 20 | 2 | Food processing, pharmaceuticals |

Key Industry Statistics on Electric Pump Efficiency and Performance Metrics

Electric transfer pumps are crucial in today's industrial landscape, offering advantages in efficiency and performance that traditional pumps lack. Recent industry statistics indicate that electric pumps can achieve efficiency rates of up to 95%, significantly reducing energy consumption and operational costs. This high efficiency is particularly beneficial for applications requiring continuous fluid transfer, as it minimizes downtime and maximizes productivity.

In terms of performance metrics, electric transfer pumps are designed to handle a wide range of fluid types, including corrosive and viscous materials. Their performance is often quantified by flow rate, pressure output, and power consumption. For instance, high-quality electric pumps can deliver flow rates exceeding 500 gallons per minute while maintaining consistent pressure levels. Additionally, advancements in pump design and materials have enhanced durability, leading to longer service life and reduced maintenance needs. These performance characteristics make electric transfer pumps a preferred choice across various industries, from agriculture to pharmaceuticals, underscoring their role in revolutionizing fluid handling.

Comparative Analysis: Electric Transfer Pumps vs. Traditional Mechanical Pumps

When it comes to fluid handling, the choice between electric transfer pumps and traditional mechanical pumps can significantly impact efficiency and productivity. Electric transfer pumps are increasingly favored for their ease of use, reliability, and environmental benefits. Unlike mechanical pumps that rely on complex gear systems, electric pumps provide smoother operation and require less maintenance. They also eliminate the need for manual effort, making them ideal for both light and heavy-duty applications.

Tips: When choosing an electric transfer pump, consider factors such as flow rate, head height, and compatibility with the fluids you will be transferring. Additionally, assess the power source availability to ensure that the pump fits your operational needs.

On the other hand, traditional mechanical pumps may still hold value in certain settings, particularly where lower upfront costs and simple repairs are key considerations. However, they often demand regular maintenance and can be less efficient in energy consumption. Ultimately, the decision should be based on the specific requirements of your fluid handling tasks, weighing the pros and cons of each option carefully.

Tips: Regularly inspect and maintain your chosen pump type to ensure optimal performance. Familiarizing yourself with the manufacturer's guidelines can significantly extend the lifespan and efficiency of your equipment.

Innovative Technologies Enhancing Fluid Handling in Electric Transfer Pump Systems

Electric transfer pumps have transformed fluid handling across various industries, thanks to innovative technologies that enhance their efficiency and reliability. These pumps are equipped with advanced features such as variable speed controls and smart sensors that optimize performance based on real-time conditions. This allows for precise flow control, reducing energy consumption and minimizing waste while ensuring that fluid is transferred efficiently.

Moreover, the integration of IoT technology into electric transfer pump systems further revolutionizes fluid management. With the capability to monitor pump performance remotely, operators can quickly identify issues and carry out maintenance before they escalate into serious problems. This proactive approach not only extends the lifespan of pumps but also ensures consistent operation, leading to increased productivity and lower operational costs. As industries continue to embrace these innovations, electric transfer pumps become indispensable tools for effective fluid handling.

Moreover, the integration of IoT technology into electric transfer pump systems further revolutionizes fluid management. With the capability to monitor pump performance remotely, operators can quickly identify issues and carry out maintenance before they escalate into serious problems. This proactive approach not only extends the lifespan of pumps but also ensures consistent operation, leading to increased productivity and lower operational costs. As industries continue to embrace these innovations, electric transfer pumps become indispensable tools for effective fluid handling.

Market Trends and Future Projections for Electric Transfer Pump Adoption in Various Industries

The adoption of electric transfer pumps in various industries is witnessing a significant upward trend, driven by advancements in technology and the growing demand for efficient fluid management solutions. Industries such as agriculture, automotive, and manufacturing are increasingly recognizing the benefits of electric pumps over traditional mechanical options. Electric transfer pumps offer high efficiency, lower maintenance costs, and a reduced carbon footprint, aligning with the rising emphasis on sustainability and eco-friendly practices.

Future projections indicate that the electric pump market will continue to expand, particularly as industries move towards automation and smart technologies. The integration of IoT in electric transfer systems enables real-time monitoring and precise control, fostering an environment for optimized performance. As regulatory frameworks evolve and push for greener alternatives, electric transfer pumps are poised to play a critical role in shaping fluid handling methods across diverse sectors. With ongoing innovations, these pumps are expected to cater to a broader range of applications, ensuring they meet the unique demands of each industry effectively.

Related Posts

-

Exploring Innovative Chemical Pump Alternatives for Industrial Applications

-

Understanding the Importance of Bleach Pumps in Industrial Cleaning Processes

-

How to Choose the Right Chemical Transfer Pump for Your Industrial Needs

-

11 Best Soft Wash Pump Solutions for Effective Cleaning

-

Comprehensive Guide to Choosing the Right High Pressure Diaphragm Pump for Your Needs

-

How to Choose the Right 24v Water Pump for Your Irrigation Needs