How to Optimize Efficiency with High Pressure Pump Selection

In today's fast-paced industrial landscape, the selection of the right high pressure pump plays a crucial role in optimizing operational efficiency and reducing costs. According to research by Grand View Research, the global high pressure pump market is projected to reach approximately $7.9 billion by 2025, driven by increasing demand across various sectors such as oil and gas, chemical processing, and water treatment. The importance of understanding the nuances of high pressure pump technologies cannot be overstated, as inappropriate selections can lead to inefficiencies and increased maintenance costs. By focusing on the best types of high pressure pumps tailored for specific applications, organizations can harness the full potential of these systems to enhance productivity and operational reliability, ultimately leading to significant savings and improved performance.

Factors Influencing High Pressure Pump Selection for Optimal Efficiency

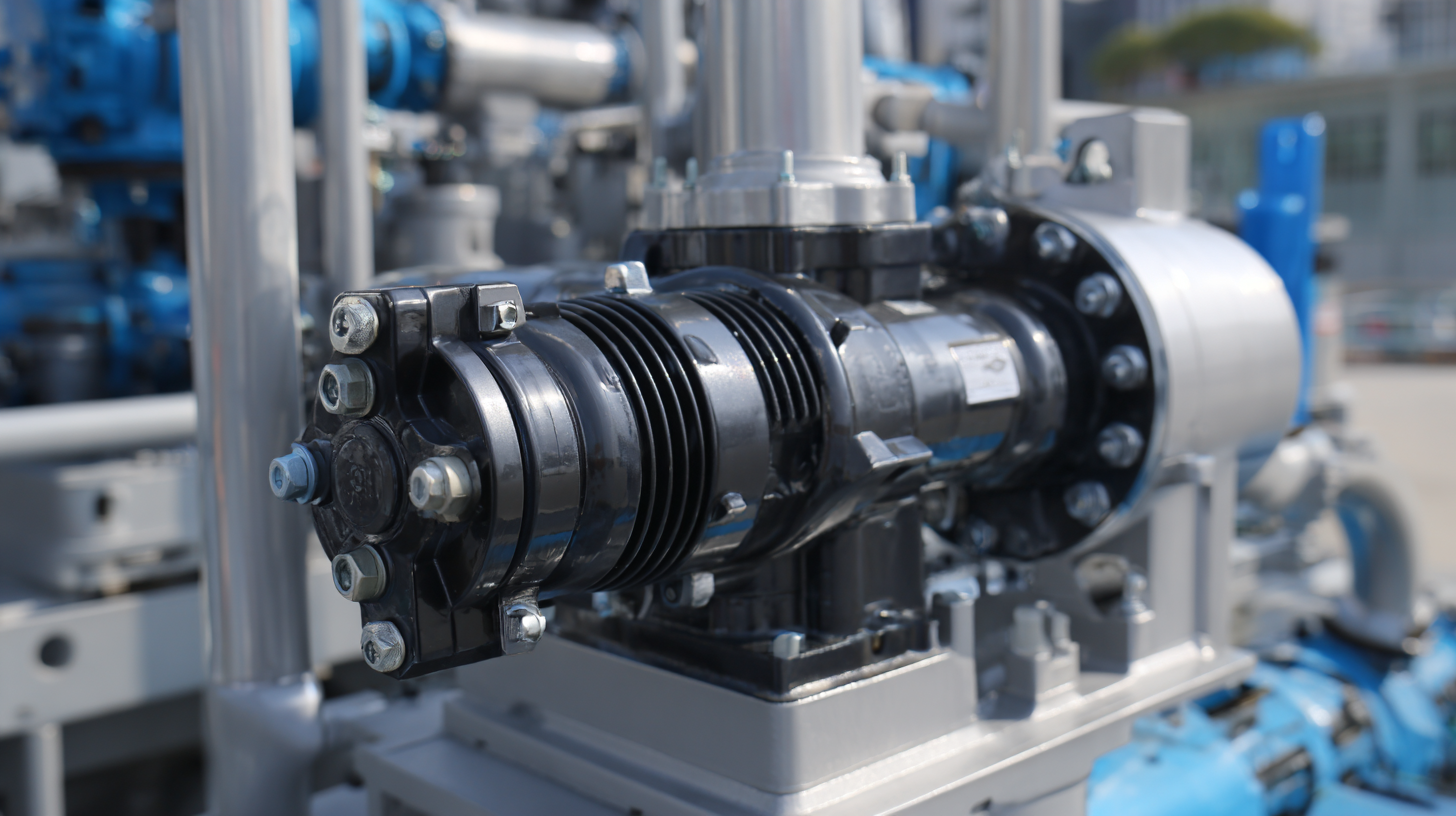

When selecting a high pressure pump for optimal efficiency, several key factors come into play that can significantly influence the overall performance of the system. One of the primary considerations is the pump's application.

Different applications, such as water treatment, industrial cleaning, or oil and gas operations, require pumps with specific pressure and flow rate characteristics. Understanding the demands of the operation ensures that the chosen pump can deliver the necessary performance without excessive energy consumption.

Another critical aspect is the pump's material construction. High pressure environments often subject pumps to harsh conditions, including corrosion and abrasion. Selecting materials that can withstand these challenges is essential not only for ensuring longevity but also for maintaining efficiency over time. Additionally, fluid viscosity and temperature are vital factors to consider, as they can affect the pump’s efficiency.

By carefully evaluating these parameters, operators can make informed choices that enhance the pump's performance, minimize downtime, and ultimately lead to cost savings in the long run.

Understanding Pump Performance Curves and Their Role in Efficiency

When selecting a high pressure pump, understanding pump performance curves is crucial for optimizing efficiency. These curves provide a visual representation of how a pump performs across different operating conditions, such as flow rate and pressure. The key elements include the pump's flow characteristics, efficiency levels, and the Net Positive Suction Head required. By analyzing these curves, engineers can identify the operating point where the pump runs efficiently, ensuring that it meets the demands of the system while minimizing energy consumption.

Moreover, deciphering pump performance curves allows for better decision-making in system design and troubleshooting. It can reveal whether the current pump meets the anticipated flow and pressure requirements or if modifications are necessary. A pump operating outside its best efficiency point (BEP) can lead to excessive energy costs and premature wear. Therefore, understanding these performance metrics not only ensures optimal operation but also extends the lifespan of the equipment while reducing potential downtimes and maintenance costs. Ultimately, the informed selection of high pressure pumps based on performance curves is integral to achieving overall operational efficiency.

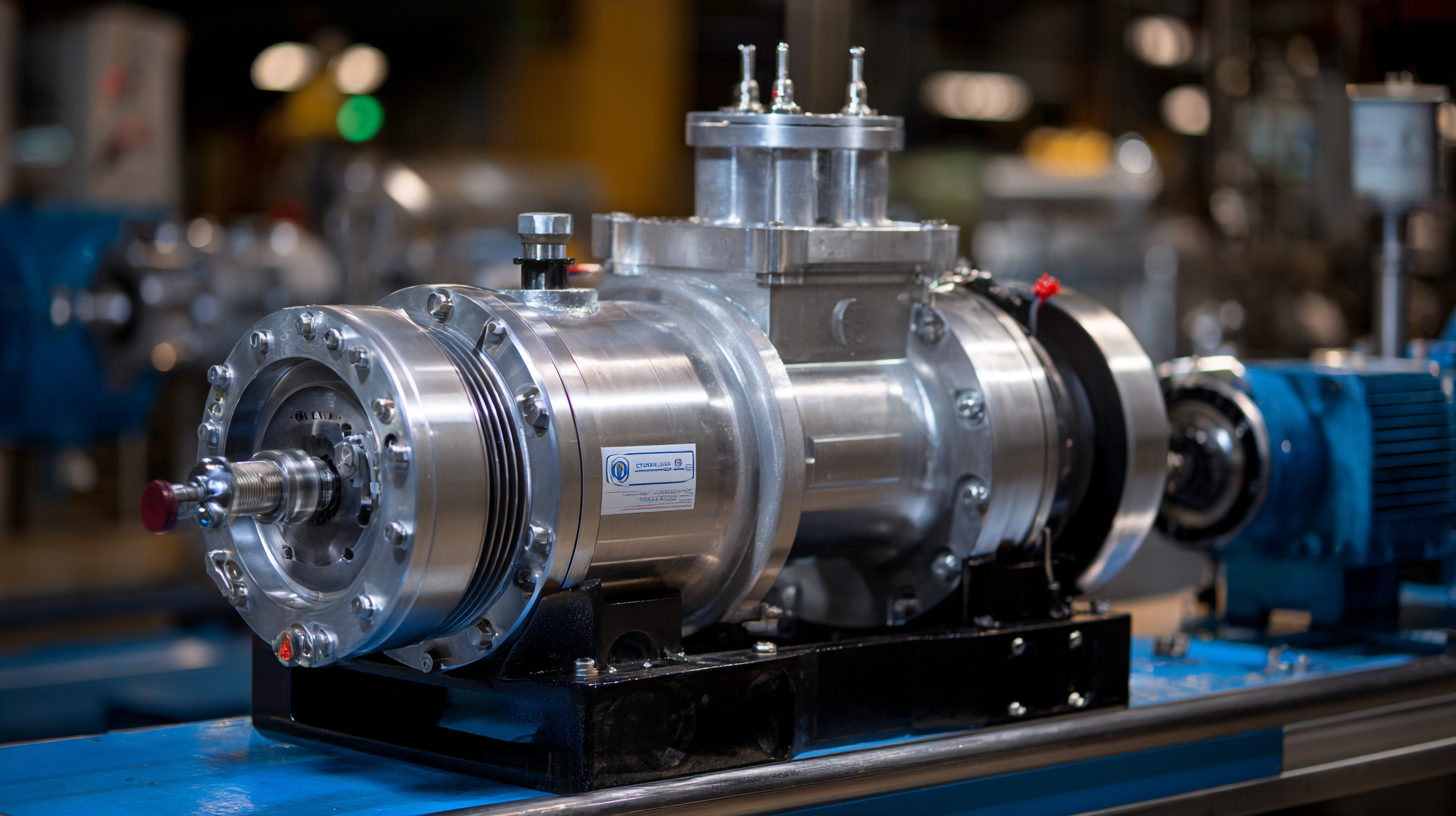

Comparative Analysis: Centrifugal vs. Positive Displacement Pumps

When selecting a high-pressure pump, understanding the distinction between centrifugal and positive displacement pumps is crucial for optimizing operational efficiency. Centrifugal pumps operate based on kinetic energy, utilizing an impeller to impart velocity to the fluid, resulting in a continuous flow. According to a report by the Hydraulic Institute, centrifugal pumps are typically favored for applications requiring high flow rates and low viscosity fluids, achieving efficiencies upwards of 85%. This makes them ideal for water supply, chemical processing, and HVAC systems where speed and volume are paramount.

On the other hand, positive displacement pumps function by trapping a fixed amount of fluid and then forcing it into the discharge pipe, making them suitable for high-viscosity solutions and precise flow control. The Global Market Insights report highlights that these pumps maintain a consistent flow rate regardless of pressure variations, which is advantageous in industries such as food processing and pharmaceuticals, where consistent metering is essential. With efficiency ratings often reaching 90% or higher, operators can achieve significant reductions in energy costs, making positive displacement pumps a wise choice for specialized applications. Understanding these dynamics is essential for making informed decisions that enhance efficiency and productivity in high-pressure operations.

Impact of Pump Material on Efficiency and Longevity in High Pressure Systems

When selecting a high-pressure pump, the material it is constructed from can significantly influence both its efficiency and longevity. Different materials respond differently to the harsh conditions typically found in high-pressure systems, such as extreme temperatures and corrosive substances.

For instance, stainless steel is often preferred for its excellent resistance to corrosion and ability to withstand high pressures, ensuring that pumps maintain their performance over time without frequent replacements or maintenance.

Furthermore, the compatibility of pump materials with the pumped fluids is crucial for optimal efficiency. Materials like plastic or specialized alloys can be employed in certain applications, particularly where corrosive or abrasive fluids are involved. Using the right material not only enhances the efficiency of the pump by minimizing wear and tear but also prolongs its service life. This careful selection process can lead to reduced operational costs and increased system reliability, ultimately making a significant impact on the overall performance of high-pressure pumping systems.

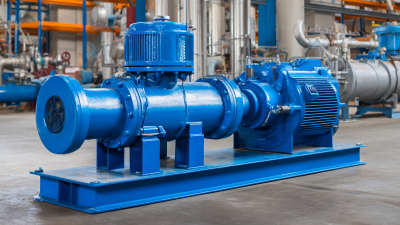

Best Practices for Maintenance to Maximize Pump Efficiency and Reliability

Maintaining a high-pressure pump is essential to optimizing its efficiency and reliability. Regular maintenance not only prolongs the life of the pump but also ensures that it operates at peak performance. One key practice is to establish a routine inspection schedule. This should include checking for any signs of wear and tear, verifying the alignment of components, and ensuring proper lubrication.

Another important tip for maintaining pump efficiency is to monitor the operating conditions closely. This includes keeping an eye on flow rates, pressure levels, and power consumption. Any deviations from the norm can indicate underlying problems that need addressing. Additionally, ensure that filters are clean and that the pump is operating within its specified parameters to avoid unnecessary strain.

Lastly, implementing a training program for personnel who operate and maintain the pumps can significantly boost overall reliability. Keeping the staff well-informed about the best practices for pump operation and maintenance can lead to quicker identification of issues, reducing downtime and repair costs. By focusing on these practices, organizations can achieve optimal pump performance while contributing to the growth of the market, which is projected to reach $1.2959 billion in 2023 and grow at a CAGR of 5.71% through 2031.

How to Optimize Efficiency with High Pressure Pump Selection - Best Practices for Maintenance to Maximize Pump Efficiency and Reliability

| Parameter | Optimal Value | Impact on Efficiency | Maintenance Frequency |

|---|---|---|---|

| Pump Type | Positive Displacement | High efficiency at varying flow rates | Yearly |

| Pressure Rating | 1000 psi | Ensures optimal performance | Every 6 months |

| Flow Rate | 50 GPM | Directly affects efficiency | Quarterly |

| Seal Condition | Good | Prevents leaks and losses | Monthly inspection |

| Fluid Characteristics | Non-viscous | Enhances flow rate | As needed |

| Temperature Range | < 180°F | Maintains mechanical integrity | Biannual |

Related Posts

-

Challenges Encountered with Submersible Pumps in Industrial Applications

-

Ultimate Guide to Choosing the Best 12 Volt Sprayer Pump for Your Agricultural Needs

-

7 Essential Tips for Choosing the Best Electric Water Pump for Your Needs

-

Exploring Innovative Alternatives to Chemical Pumps for Enhanced Efficiency and Reliability

-

Optimizing Efficiency: Essential Strategies for Chemical Transfer Pump Performance in Industry

-

How to Choose the Best Pressure Pump for Water Efficiency Based on Industry Standards