How to Optimize Your 12V Diaphragm Pump for Maximum Efficiency and Performance

In an era where energy efficiency and performance are paramount, optimizing the diaphragm pump 12v has become a crucial aspect for various applications in industries ranging from automotive to aquaculture. According to a recent report by the International Energy Agency (IEA), fluid transport accounts for approximately 20% of industrial energy consumption. Efficient pumps not only reduce operational costs but also contribute to sustainability efforts by minimizing energy waste. Moreover, advancements in diaphragm pump designs have demonstrated that improvements in efficiency can yield energy savings of up to 30%, making them a vital component in enhancing overall system performance. By employing best practices and innovative approaches in the optimization process, users can unlock the full potential of their diaphragm pump 12v, ensuring peak performance and reliability in demanding environments.

Maximizing Flow Rate: Understanding the Impact of Voltage and Amperage on 12V Diaphragm Pumps

When optimizing a 12V diaphragm pump for maximum efficiency, understanding the interplay between voltage and amperage is crucial. Voltage acts as the driving force for the pump, directly influencing its flow rate. A higher voltage can lead to increased pump speed, resulting in greater fluid movement. However, operating above the recommended voltage can cause excessive wear and overheating, potentially damaging the pump. Therefore, it's essential to stay within specified voltage limits while fine-tuning the system for optimal performance.

Amperage, on the other hand, is an indicator of the pump's power consumption and the load it is under. When optimizing for maximum flow rate, monitoring amperage helps ensure the pump is not overworked. If the amperage is consistently peaking at high levels, adjustments such as reducing the load or maintaining proper fluid levels can be beneficial. Balancing voltage and amperage effectively allows for enhanced performance of the 12V diaphragm pump, ensuring that it operates efficiently without compromising its durability and lifespan.

How to Optimize Your 12V Diaphragm Pump for Maximum Efficiency and Performance

| Pump Model | Voltage (V) | Amperage (A) | Flow Rate (L/min) | Efficiency (%) |

|---|---|---|---|---|

| Model A | 12 | 4.5 | 5.0 | 80 |

| Model B | 12 | 3.0 | 7.0 | 85 |

| Model C | 12 | 5.5 | 4.5 | 75 |

| Model D | 12 | 4.0 | 6.5 | 82 |

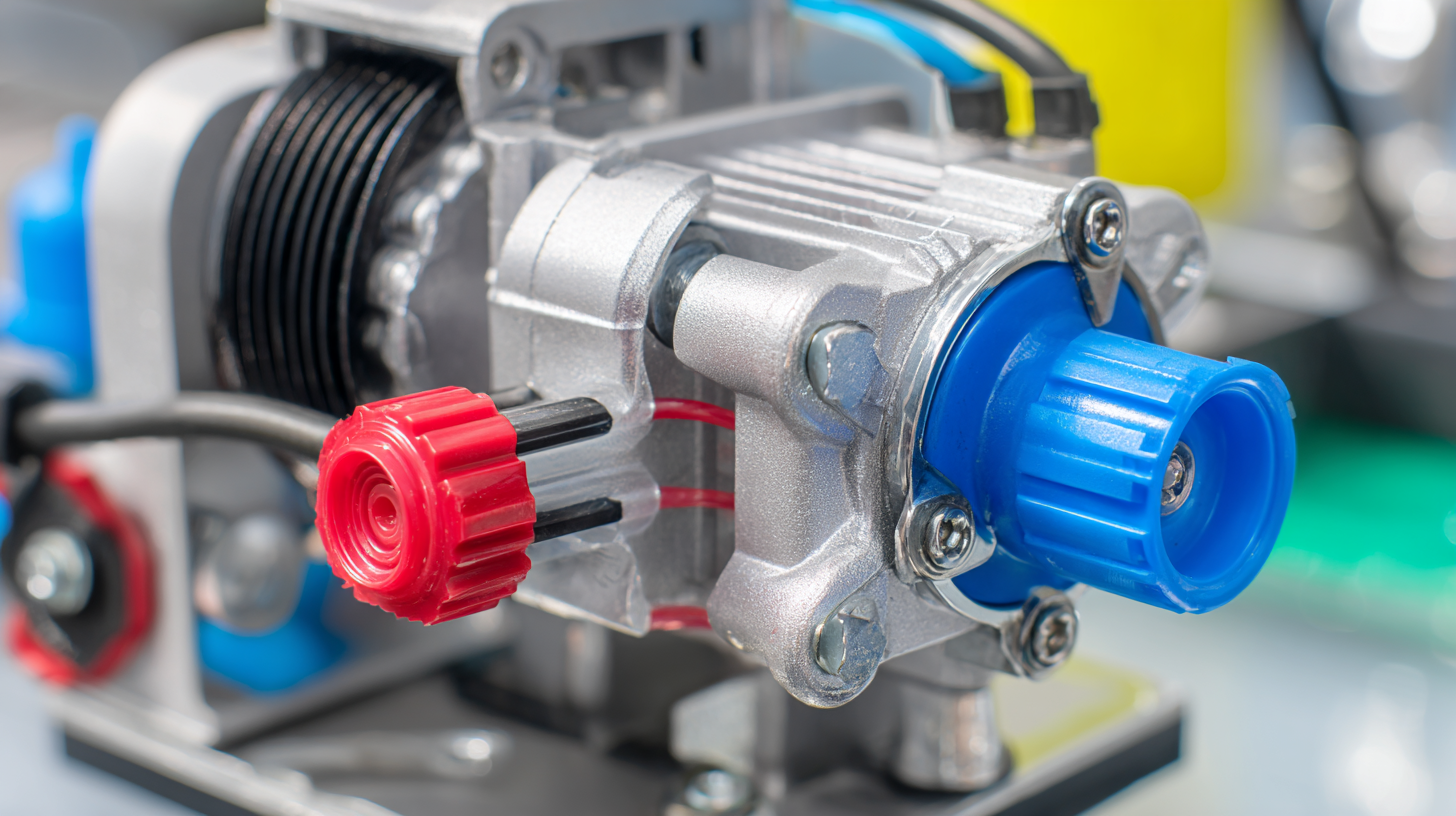

Choosing the Right Materials: How Pump Construction Influences Efficiency and Durability

The construction materials of a 12V diaphragm pump significantly influence its overall efficiency and durability. According to a report by the Hydraulic Institute, selecting the right elastomers for the diaphragm can lead to an increase in pump performance by approximately 15% due to enhanced chemical resistance and reduced wear over time. Materials such as EPDM and Viton are often recommended for their durability and resilience in various operating conditions, ensuring that the pump can maintain efficiency under varying temperatures and pressures.

In addition to diaphragm materials, the choice of housing materials also plays a crucial role in minimizing energy losses. A study conducted by the American Society of Mechanical Engineers (ASME) indicated that pumps constructed from high-strength polymers exhibit less friction and can improve energy efficiency by roughly 10% compared to those made from traditional metals. Furthermore, using corrosion-resistant coatings can extend the lifespan of the pump, thereby reducing the need for replacements, which enhances the pump’s overall performance and reliability in demanding applications. Adopting these material advancements can significantly contribute to optimizing a 12V diaphragm pump's efficiency and durability.

The Role of Maintenance: Best Practices for Ensuring Long-Term Performance of 12V Diaphragm Pumps

Proper maintenance of your 12V diaphragm pump is crucial for ensuring its long-term performance and efficiency. Regularly checking the pump for wear and tear can prevent potential failures. Inspecting and cleaning the diaphragm and valves will help maintain optimal flow rates and pressure. Additionally, ensure that all electrical connections are secure and free from corrosion to avoid unexpected disruptions in performance.

Tips for maintaining your diaphragm pump include creating a routine maintenance schedule to catch any issues early. Replace worn parts promptly to avoid further damage. Additionally, choosing the right pump size for your application will help maximize efficiency. By ensuring that your pump operates within its designed flow range, you can extend its lifespan and improve overall functionality.

Another important practice is to routinely flush the pump with clean water to remove any debris or buildup that may hinder performance. Keeping the pump environment clean and dry will also prevent rust and corrosion, further enhancing its durability. By integrating these maintenance best practices, you can significantly optimize your 12V diaphragm pump, ensuring it works effectively for years to come.

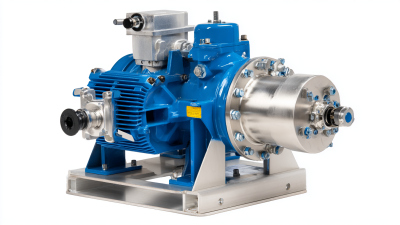

Optimizing Pump Design: Leveraging Advanced Technology for Improved Efficiency and Output

The home water pump market is set for significant growth, projected to reach a value of $18.58 billion in 2024 and escalate to $26.92 billion by 2032, at a CAGR of 4.8%. This trend highlights an increasing demand for optimized pump designs that capitalize on advanced technology to improve efficiency and output. As manufacturers embrace modern innovations, the integration of smart control systems and materials designed for enhanced performance will be crucial in addressing market needs.

In parallel, sectors such as diesel urea pumps are also experiencing notable expansion, with market values growing from $350 million in 2022 to an anticipated $620 million by 2030, reflecting a 7.0% CAGR. The rising focus on optimizing pump systems for energy efficiency not only boosts production capabilities but also extends the lifespan of components, particularly in high-brightness LED applications, where longevity is essential for solid-state lighting developments. Emphasizing advanced technological integration will be pivotal in fostering sustainable growth across various pump categories in the coming years.

Performance Under Pressure: Evaluating the Effects of System Head and Back Pressure on Pump Efficiency

When optimizing a 12V diaphragm pump, understanding the implications of system head and back pressure is crucial for maximizing efficiency and performance.

System head refers to the total height that the pump must overcome to move fluid, which can significantly impact the workload on the pump.

An increase in system head demands more energy from the pump, which can lead to reduced efficiency if not addressed.

Therefore, it is essential to carefully design the system to minimize unnecessary elevation changes and to choose a pump that matches the required head specifications.

Back pressure also plays a pivotal role in pump performance.

It refers to the pressure exerted against the pump's output, which can limit the flow rate and overall efficiency.

In many applications, managing back pressure can be a balancing act;

too much can hinder performance, while too little might not utilize the pump's capabilities effectively.

Implementing appropriate control valves or bypass systems can help regulate back pressure, allowing the pump to operate within its optimal range.

Regular assessment of these parameters will ensure that the diaphragm pump continues to function efficiently under varying operational conditions.

Related Posts

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Needs

-

Comprehensive Guide to Choosing the Right High Pressure Diaphragm Pump for Your Needs

-

How to Choose the Right 24v Water Pump for Your Irrigation Needs

-

Exploring Innovative Alternatives to Chemical Pumps for Enhanced Efficiency and Reliability

-

5 Smart Tips to Choose the Best Small Electric Water Pump

-

Ultimate Guide to Choosing the Best 12 Volt Sprayer Pump for Your Agricultural Needs