Understanding the Importance of Bleach Pumps in Industrial Cleaning Processes

In the realm of industrial cleaning processes, the significance of bleach pumps cannot be overstated. These specialized devices play a crucial role in the effective and efficient application of bleach solutions for sanitizing and disinfecting various environments, ranging from manufacturing facilities to healthcare settings.

Understanding how to leverage bleach pumps not only optimizes cleaning protocols but also ensures compliance with safety standards and enhances operational efficiency. This guide will delve into the essential aspects of bleach pumps, including their functionality, maintenance, and the best practices for integrating them into cleaning processes.

By recognizing the importance of a reliable bleach pump, organizations can significantly improve their cleaning outcomes and contribute to a safer, cleaner work environment.

Role of Bleach Pumps in Ensuring Effective Disinfection in Industrial Settings

In industrial settings, the role of bleach pumps is critical for ensuring effective disinfection, particularly in the fight against healthcare-associated infections (HAIs). As the industry continuously seeks advancements in infection control, the use of bleach pumps facilitates the reliable and precise delivery of bleach solutions, which are essential for maintaining sanitation in various facilities. A recent report highlighted that properly dosed bleach solutions can reduce pathogen levels by up to 99.9%, showcasing the importance of accurate dispensing systems in achieving optimal disinfection levels.

Moreover, as facilities increasingly integrate options like sporicides and quaternary ammonium compounds, the reliability of bleach pumps becomes even more vital. Using bleach pumps not only enhances the effectiveness of the cleaning agents applied but also supports compliance with safety regulations. For instance, a study indicated that utilizing automated bleach pump systems can significantly lower the risk of human error in chemical application, thereby improving overall safety and efficacy in cleaning processes. The integration of these technologies plays an essential part in upholding stringent sanitation standards across various industrial environments.

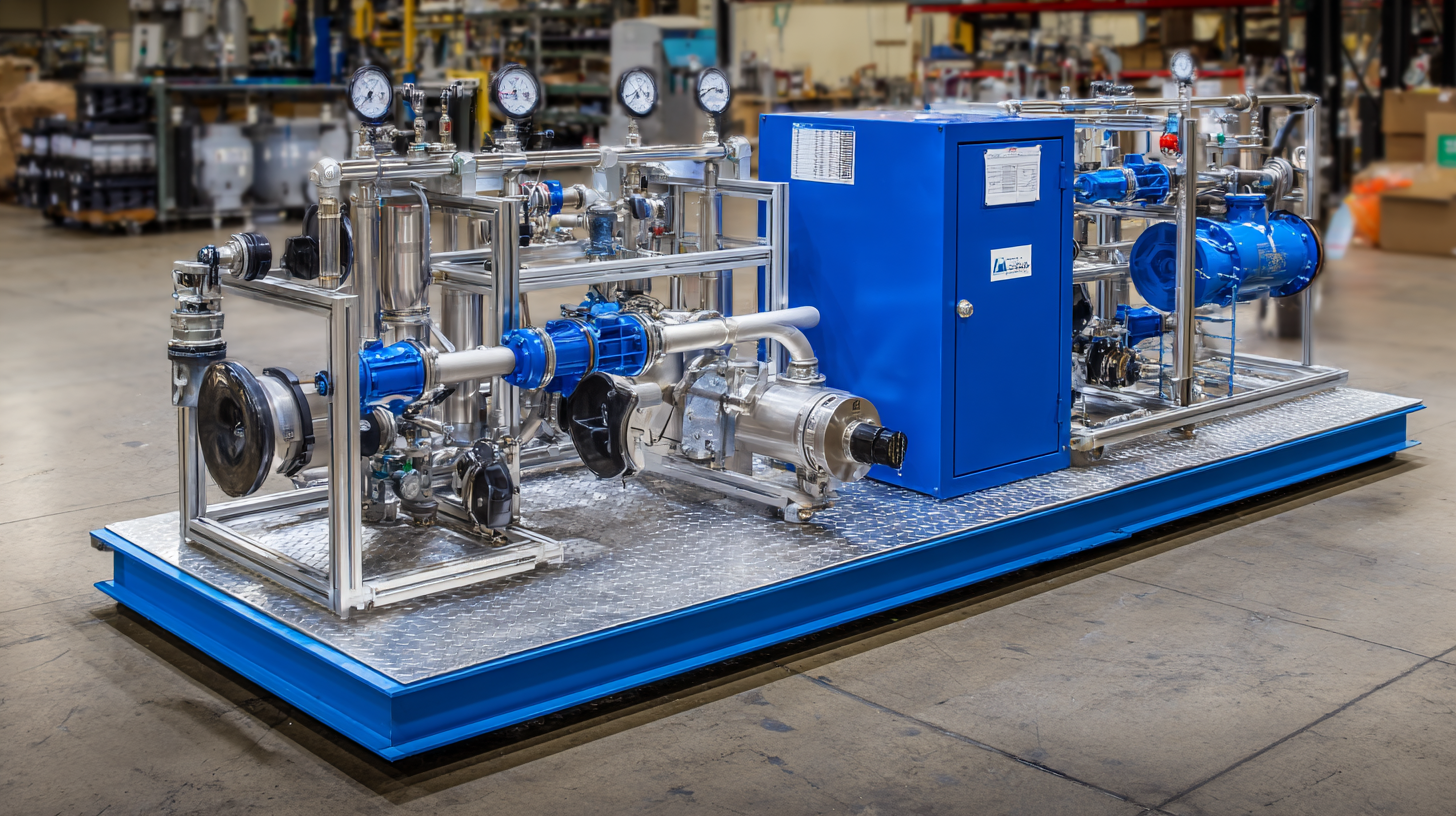

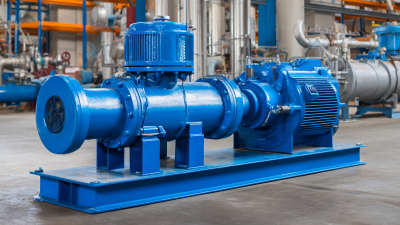

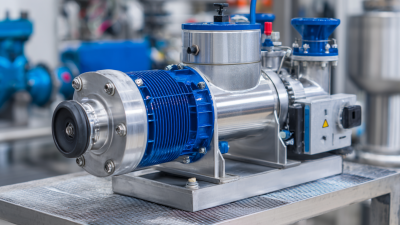

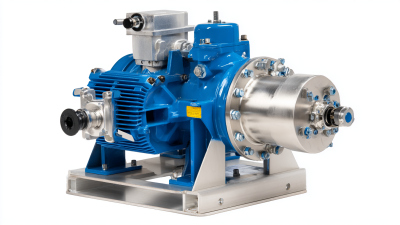

Key Features and Specifications of Industrial Bleach Pumps for Optimal Performance

When it comes to industrial cleaning processes, bleach pumps play a crucial role in ensuring efficiency and safety. These pumps are specifically designed to handle the corrosive nature of bleach while maintaining optimal performance. Key features of industrial bleach pumps include high durability materials, such as PVC or polypropylene, which resist chemical degradation. Additionally, these pumps often have robust sealing systems to prevent leaks, and their flow rates can be adjusted to meet different operational needs.

When it comes to industrial cleaning processes, bleach pumps play a crucial role in ensuring efficiency and safety. These pumps are specifically designed to handle the corrosive nature of bleach while maintaining optimal performance. Key features of industrial bleach pumps include high durability materials, such as PVC or polypropylene, which resist chemical degradation. Additionally, these pumps often have robust sealing systems to prevent leaks, and their flow rates can be adjusted to meet different operational needs.

When selecting a bleach pump, consider the specifications carefully. Look for pumps that offer features like variable speed control and self-priming capabilities, which enhance flexibility and ease of use in various applications. Streams of concentrated bleach can be effectively managed when using well-maintained pumps that are suited for the job.

Tips: Always ensure that the pump to be used is compatible with the specific concentration of bleach you plan to utilize. Regular maintenance checks can prevent potential failures and prolong the lifespan of the equipment. Additionally, invest in protective gear when operating bleach pumps to safeguard against any accidents during cleaning processes.

Economic Impact of Using Automated Bleach Pumps in Large-Scale Cleaning Operations

Automated bleach pumps play a crucial role in enhancing the efficiency of large-scale cleaning operations, significantly impacting the economic landscape of industrial cleaning processes. By automating the bleach application, companies can optimize chemical usage, ensuring that the right amounts are delivered precisely when needed. This not only reduces waste but also minimizes labor costs, as less manual handling is required, allowing staff to focus on more strategic tasks.

Moreover, the employment of automated bleach pumps can lead to enhanced safety and compliance with health regulations. Since bleach is a potent disinfectant, its improper handling can pose risks to workers’ health and safety. Automated systems mitigate these risks by reducing human exposure and ensuring that the operation adheres to necessary safety standards. As a result, businesses can not only cut down on operational costs but also potentially lower their insurance premiums due to improved safety measures. This positive economic impact, coupled with increased operational efficiency, underscores the importance of integrating automated bleach pumps into large-scale cleaning operations.

Safety Considerations and Best Practices for Operating Bleach Pumps in the Workplace

When operating bleach pumps in industrial cleaning processes, safety considerations are paramount. According to the U.S. Occupational Safety and Health Administration (OSHA), exposure to sodium hypochlorite, the active ingredient in bleach, can result in respiratory issues, skin irritation, and other health problems if not handled properly. Therefore, personal protective equipment (PPE) such as gloves, goggles, and respiratory masks is essential for all employees involved in the operation and maintenance of bleach pumps.

In addition to PPE, best practices for operating bleach pumps should include regular training sessions for employees. A study published by the National Institute for Occupational Safety and Health (NIOSH) indicates that ongoing education significantly reduces the likelihood of accidents and exposure-related incidents in workplaces where hazardous chemicals are handled.

Routine inspections and maintenance of bleach pumps are also crucial, as they help identify potential leaks and malfunctions that could lead to dangerous spills. Implementing a structured protocol for bleach pump operation not only ensures safety but also enhances efficiency, making industrial cleaning processes safer for everyone involved.

Trends in Bleach Pump Technology and Their Implications for Future Industrial Cleaning Solutions

The advancements in bleach pump technology are increasingly shaping the industrial cleaning landscape. Recent studies have highlighted the significant impact of cleaning products, including bleach, on indoor air quality and human health, emphasizing the necessity of efficient distribution systems, such as bleach pumps, that can dispense these substances safely and effectively. The integration of smart technologies in bleach pumps allows for real-time monitoring and precise control of chemical concentrations, which not only enhances cleaning efficacy but also minimizes the potential risks associated with overuse.

As industries shift towards more sustainable practices, the role of bleach pumps is evolving. The demand for environmentally friendly cleaning solutions has led to innovations that reduce water consumption and chemical waste during the bleaching process. Consequently, future developments in bleach pump technology are likely to focus on increasing efficiency while reducing environmental impact, addressing both regulatory pressures and consumer expectations for safe, effective cleaning solutions that contribute to better indoor air quality. This trend towards sustainable and health-conscious industrial cleaning products is essential as companies strive to meet new environmental standards and consumer preferences.

Related Posts

-

Exploring Innovative Chemical Pump Alternatives for Industrial Applications

-

How to Choose the Best Pressure Pump for Water Efficiency Based on Industry Standards

-

How to Choose the Right Chemical Transfer Pump for Your Industrial Needs

-

7 Incredible Benefits of Using Fountain Pumps for Your Water Features

-

7 Essential Tips for Choosing the Best Electric Water Pump for Your Needs

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Needs