Comprehensive Guide to Choosing the Right High Pressure Diaphragm Pump for Your Needs

When it comes to selecting the perfect high pressure diaphragm pump for your specific applications, understanding the various features and capabilities is paramount. With a multitude of options available in the market, choosing the right pump can significantly impact the efficiency and effectiveness of your operations. In this comprehensive guide, we aim to break down the key factors to consider, from the pump's design and materials to its performance characteristics and maintenance requirements. Whether you're in the chemical processing industry, wastewater management, or any other field that demands reliability and high-pressure performance, this guide will help you navigate through the intricacies of high pressure diaphragm pumps. By the end, you'll be equipped with the knowledge to make an informed decision that best suits your needs, ensuring optimal performance and longevity of your chosen pump.

What to Look for in a High Pressure Diaphragm Pump: Key Features Explained

When selecting a high pressure diaphragm pump, it’s essential to understand the key features that can significantly impact performance and durability. One of the most critical factors is the pump's maximum pressure rating, typically ranging from 30 PSI to upwards of 1200 PSI, depending on the application. According to a 2022 market analysis by Research and Markets, high pressure diaphragm pumps are expected to see a compound annual growth rate (CAGR) of 6.5% through 2027, highlighting their increasing demand in various industries, including chemicals and pharmaceuticals.

Another important feature to consider is the material of the diaphragm itself. Rubber, PTFE, and thermoplastic elastomers are commonly used materials, each offering different levels of chemical resistance and durability. A detailed report from MarketsandMarkets indicates that pumps made from PTFE boast longer lifespans in corrosive environments, allowing for reduced maintenance costs and increased efficiency. Additionally, pump size and flow rate are critical, as they determine how much fluid can be moved through the system. Understanding these features will empower users to make informed decisions and select a pump that meets their specific operational requirements.

Understanding Different Types of High Pressure Diaphragm Pumps Available on the Market

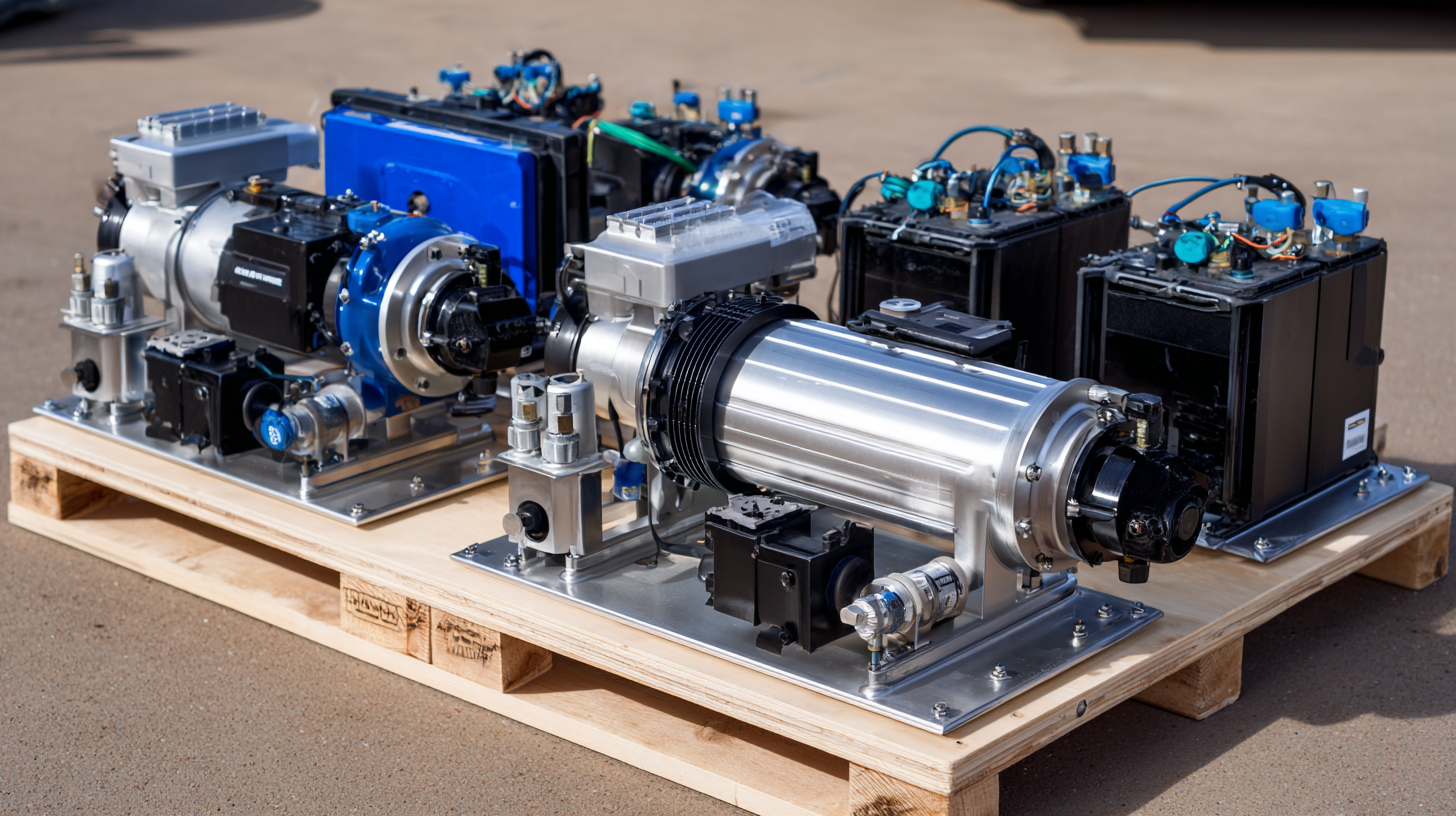

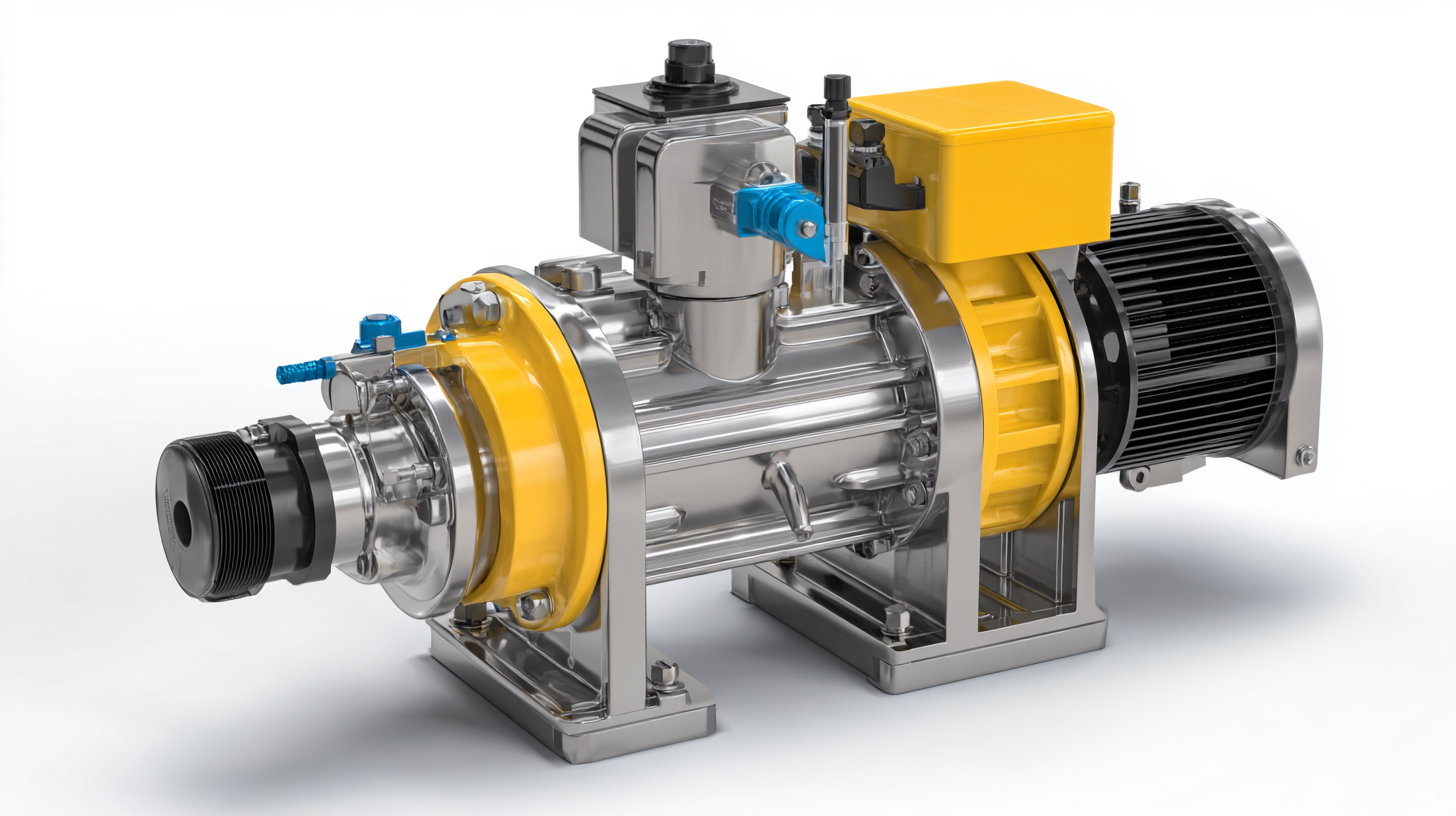

When selecting a high pressure diaphragm pump, it's essential to understand the various types available on the market. High pressure diaphragm pumps are designed to handle different fluids and operating conditions, so knowing their specific characteristics can help you make an informed decision. Generally, the main types include air-operated, electric-driven, and hydraulic diaphragm pumps. Each type has its unique advantages and is suited for specific applications, whether in industrial processes, water treatment, or chemical transfer.

When selecting a high pressure diaphragm pump, it's essential to understand the various types available on the market. High pressure diaphragm pumps are designed to handle different fluids and operating conditions, so knowing their specific characteristics can help you make an informed decision. Generally, the main types include air-operated, electric-driven, and hydraulic diaphragm pumps. Each type has its unique advantages and is suited for specific applications, whether in industrial processes, water treatment, or chemical transfer.

Air-operated diaphragm pumps are popular due to their simplicity and versatility. They can handle a wide range of fluids, from water to viscous substances, making them ideal for many industries. Electric-driven diaphragm pumps, on the other hand, offer precision and efficiency, often featuring variable speed drives that allow for exact flow control. Finally, hydraulic diaphragm pumps excel in applications requiring high pressure and are known for their durability and ability to work with abrasive fluids. Understanding these fundamental differences will guide you in choosing a pump that best suits your operational needs.

Top 5 Brands of High Pressure Diaphragm Pumps and Their Unique Advantages

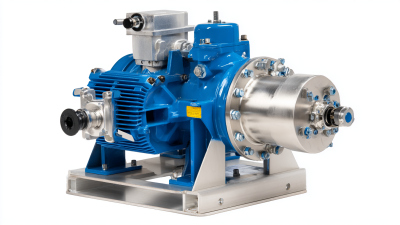

When selecting a high-pressure diaphragm pump, understanding the leading brands and their unique advantages is crucial. According to a recent market analysis by Technavio, the global diaphragm pump market is projected to grow at a CAGR of 4% from 2021 to 2025, driven by increasing demand across various industries including water treatment and chemical processing. Among the top brands, Graco stands out for its robust construction and versatility. Their pumps are designed to handle a variety of fluids, making them ideal for applications that require high reliability and efficiency.

Another noteworthy brand is Wilden, known for its innovative AODD (air-operated double diaphragm) technology. Wilden's pumps offer exceptional performance with a flow rate range of up to 140 gallons per minute, making them well-suited for handling difficult fluids. According to a report by MarketWatch, Wilden has captured a significant market share due to its emphasis on energy efficiency, reducing operational costs for users. Similarly, you have VPS (Viking Pump Solutions), which is recognized for its compact design and ease of maintenance. Their products typically feature a higher suction lift and lower noise levels, fulfilling specific needs in tight or sensitive work environments.

Comprehensive Guide to Choosing the Right High Pressure Diaphragm Pump for Your Needs

| Pump Model | Max Pressure (psi) | Flow Rate (GPM) | Material | Weight (lbs) | Application |

|---|---|---|---|---|---|

| Model A | 150 | 5.0 | Stainless Steel | 45 | Chemical Transfer |

| Model B | 200 | 6.5 | Polypropylene | 50 | Water Treatment |

| Model C | 175 | 4.0 | Aluminum | 35 | Oil Transfer |

| Model D | 220 | 7.0 | Nylon | 55 | Food Processing |

| Model E | 180 | 5.5 | Brass | 42 | Paint Transfer |

Cost Considerations: How to Optimize Your Budget for a High Pressure Diaphragm Pump

When selecting a high pressure diaphragm pump, cost considerations are paramount. Budgeting effectively can ensure you acquire a pump that meets your operational needs without overspending. Start by analyzing your specific requirements – the flow rate, pressure, and the fluid being pumped can all impact the final cost. Research different brands and models to get a sense of the price range and potential long-term savings.

**Tips:** Always consider the total cost of ownership. This includes not only the purchase price but also maintenance and operational costs. A more upfront investment in a durable and efficient pump can lead to lower overall costs in the long run. Additionally, look for pumps with easy access to spare parts and service support.

Another strategy is to explore financing options or seek out used or refurbished pumps. This can significantly reduce the initial expenditure. However, ensure that the quality and reliability of these options meet your operational standards, as compromising in this area could lead to higher costs in repairs and downtime.

Cost Considerations for High Pressure Diaphragm Pumps

Essential Maintenance Tips to Extend the Life of Your High Pressure Diaphragm Pump

Maintaining a high-pressure diaphragm pump is crucial for ensuring optimal performance and longevity. Regular maintenance can significantly reduce the risk of failures and extend the pump's lifespan by up to 30%, according to the Fluid Pumping System Reliability Report. One essential maintenance tip is to routinely inspect and replace worn-out diaphragms. This component is vital for the pump's functionality, and neglecting it can lead to reduced efficiency and increased operational costs.

Another important aspect of maintenance involves monitoring the pump's pressure settings and ensuring they align with manufacturer specifications. Research from the Pump Industry Statistics shows that improper pressure adjustments account for nearly 25% of service-related issues in diaphragm pumps. Furthermore, keeping the pump clean and free of contaminants can prevent premature wear and tear, ultimately maintaining the pump's efficiency. Following these essential maintenance tips will help ensure that your high-pressure diaphragm pump continues to perform at its best for years to come.

Related Posts

-

Troubleshooting Issues with Dual Diaphragm Pumps for Optimal Performance

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Needs

-

Exploring Innovative Alternatives to Chemical Pumps for Enhanced Efficiency and Reliability

-

Optimizing Efficiency: Essential Strategies for Chemical Transfer Pump Performance in Industry

-

What is the Functionality of a Water Tank Pump in Modern Water Systems

-

What to Know About Diaphragm Vacuum Pumps: A Comprehensive Guide for Global Buyers