7 Essential Tips for Choosing the Right Diaphragm Pump for Your Needs

Choosing the right diaphragm pump for your needs is a critical decision that can significantly impact efficiency and operational costs in various industries. According to recent market research reports, the diaphragm pump segment is expected to experience substantial growth, projected to reach $3.02 billion by 2026, driven by increasing demand in sectors such as water treatment, oil and gas, and chemical processing. The versatility of diaphragm pumps allows them to handle a variety of fluids, including abrasives and corrosive materials, making them indispensable in many applications.

However, selecting the right diaphragm pump requires careful consideration of multiple factors such as flow rate, pressure ratings, and material compatibility. In this guide, we will provide seven essential tips to help you navigate this complex landscape and ensure that your diaphragm pump aligns with your specific operational needs.

Understanding the Different Types of Diaphragm Pumps Available on the Market

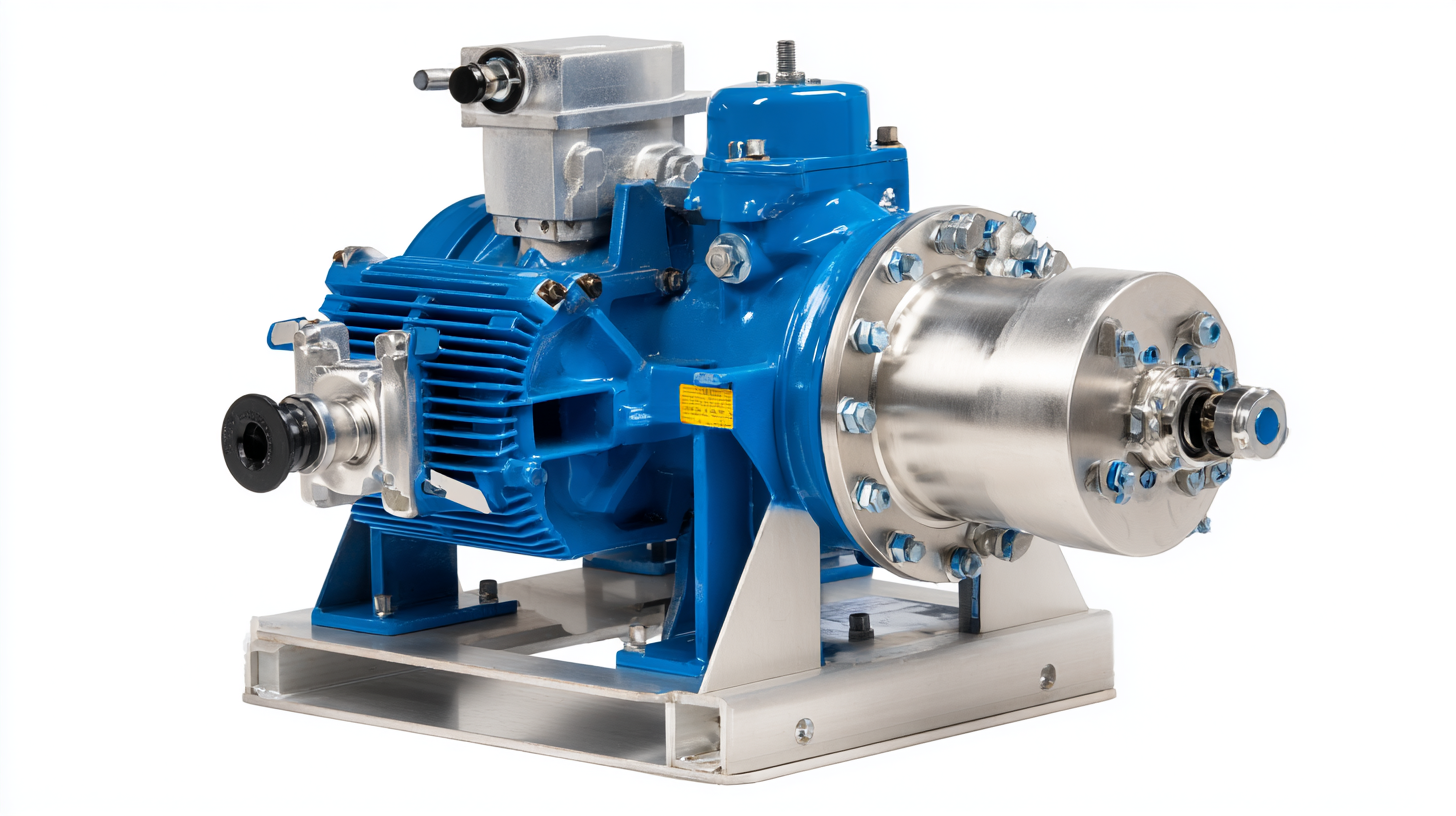

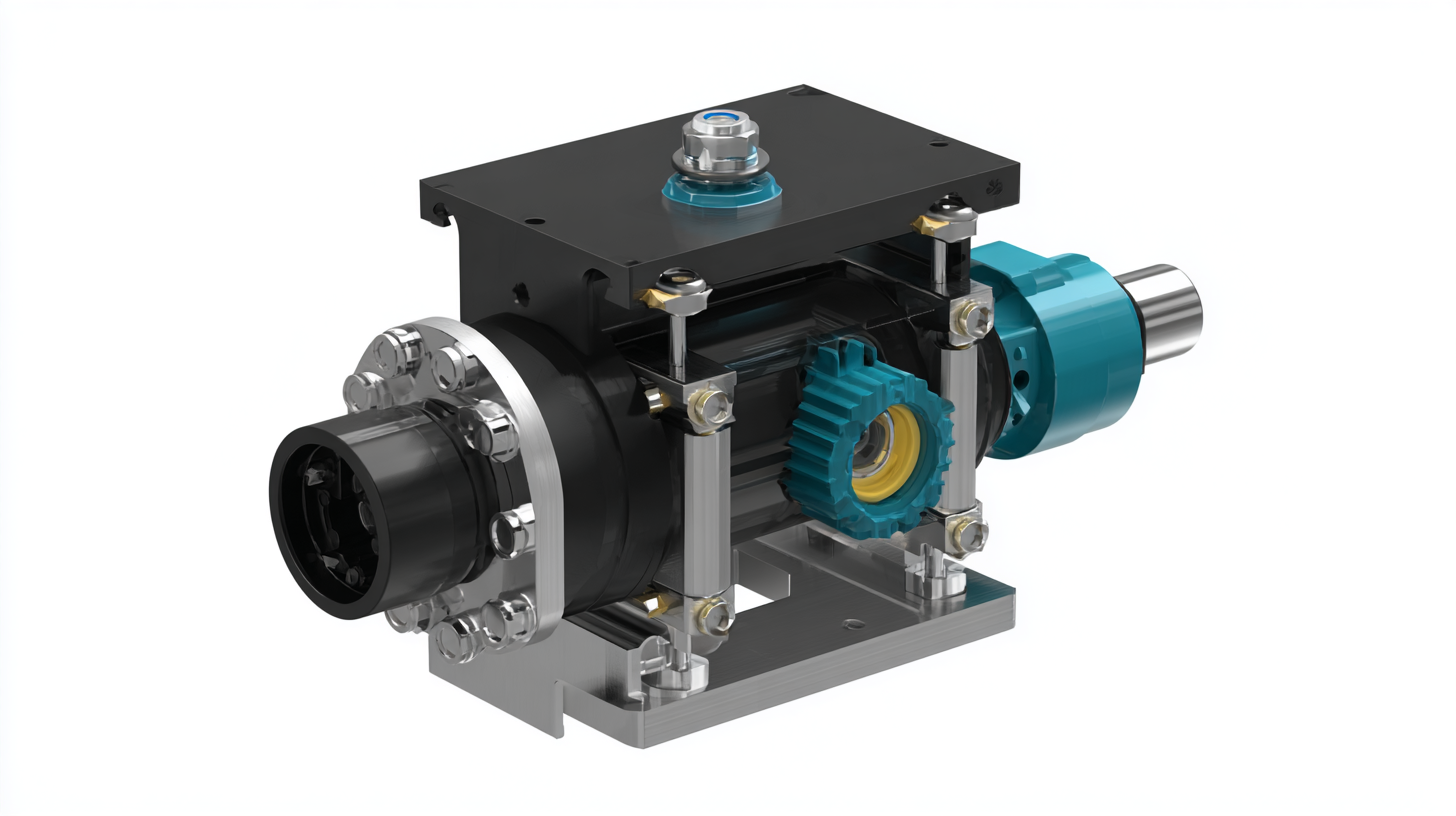

When it comes to selecting the right diaphragm pump, understanding the various types available is crucial. Diaphragm pumps are becoming increasingly popular across various industries due to their efficiency and versatility. They are extensively used in applications related to chemicals, pharmaceuticals, and water treatment, which is reflected in the growth of the diaphragm pump market. As industries expand, the demand for reliable pumps is driving innovation and leading to a broader range of options for consumers.

One essential tip for choosing the right diaphragm pump is to consider the specific application requirements. Different types of diaphragm pumps, such as those designed for high-pressure applications or those suited for handling abrasive materials, can significantly impact performance. Additionally, evaluating the pump’s materials of construction is vital, especially when dealing with corrosive substances. Another key factor is the flow rate and pressure requirements; ensure that the pump you select can meet the demands of your operation while maintaining efficiency.

Lastly, don't overlook the importance of the pump's maintenance needs. Some diaphragm pumps may require more frequent servicing than others, which can affect overall operational costs. By understanding these considerations and staying informed about market trends, you can make a more informed decision and choose a diaphragm pump that best fits your needs.

Key Factors to Consider When Assessing Pump Flow Rates and Pressure Requirements

When selecting a diaphragm pump, understanding flow rates and pressure requirements is vital to ensure optimal performance for your specific application. Start by assessing the required flow rate for your system. This will dictate how much fluid the pump needs to move in a given timeframe. Keep in mind that different applications may demand varying flow rates, so consider conducting a thorough analysis of your process needs to avoid any potential bottlenecks.

Next, evaluate the pressure requirements that your system will encounter. Diaphragm pumps come with different pressure ratings, and selecting one that can handle the maximum pressure of your application is crucial. Insufficient pressure capabilities can lead to ineffective operation and even system damage. Additionally, consider environmental factors, such as temperature and chemical compatibility, as they might influence the pump’s performance under pressure.

Finally, it’s worth noting that operational efficiency can be impacted by the pump's design and material. For optimal efficiency, choose pumps made from durable materials that can withstand the operational environment, while providing the necessary flow and pressure specifications. Careful consideration of these key factors will help you choose a diaphragm pump that not only meets your immediate needs but also promises reliability and longevity.

Flow Rate and Pressure Requirements of Diaphragm Pumps

The Importance of Material Compatibility in Diaphragm Pump Selection

When selecting a diaphragm pump, one of the most critical factors to consider is material compatibility. This is particularly vital when dealing with hazardous or corrosive chemicals, as improper materials can lead to pump failure and safety hazards. According to industry reports, nearly 30% of pump failures are attributed to material incompatibility, highlighting the need for careful selection. Using the right materials can significantly improve the lifespan of the pump and ensure safe handling of dangerous substances.

Tip 1: Always consult the manufacturer’s chemical compatibility charts before making a selection. These charts provide essential data about how different materials will react with specific chemicals, helping you avoid costly mistakes.

Moreover, energy efficiency is paramount in today’s industrial environment. Using air-operated double diaphragm (AODD) pumps can enhance energy efficiency while maintaining reliable performance. In a recent study, it was found that AODD pumps operate at up to 90% efficiency in transferring hazardous chemicals, making them a suitable choice for applications where energy savings and safety are priorities.

Tip 2: Evaluate the flow requirements and the chemical properties of your application. Consider factors such as viscosity and temperature, as these can affect pump performance. Choosing a diaphragm pump designed for your specific needs ensures optimal operation and longevity.

How to Evaluate the Pump’s Ease of Maintenance and Repair Options

When selecting a diaphragm pump, evaluating the ease of maintenance and repair options is crucial to ensure long-term functionality and minimize downtime. One of the first steps is to analyze the pump design—look for accessible components that allow for quick disassembly and reassembly. Pumps with fewer complex parts are generally simpler to maintain, reducing the need for specialized tools or skills during repairs. Additionally, consider the availability of replacement parts; a manufacturer that offers readily available components can drastically simplify the repair process.

Another important factor is the documentation provided with the pump. A comprehensive user manual can guide operators through maintenance routines and troubleshooting steps effectively. Opt for pumps from manufacturers that offer robust customer support and technical assistance, as this can be a vital resource when facing challenging repairs. Finally, inquire about the warranty and service agreements, which can further safeguard your investment by ensuring professional service when needed. By focusing on these aspects, you can select a diaphragm pump that is not just efficient but also easy to maintain throughout its operational life.

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Needs

| Feature | Importance | Ease of Maintenance | Repair Options |

|---|---|---|---|

| Material Compatibility | High | Moderate | Available |

| Flow Rate | Critical | Easy | Limited |

| Pressure Rating | Essential | Difficult | Available |

| Self-Priming Capability | High | Easy | Moderate |

| Power Source | Important | Moderate | Available |

| Port Size | Moderate | Easy | Limited |

| Weight & Portability | Moderate | Easy | Available |

Budgeting for Your Diaphragm Pump: Cost vs. Performance Analysis

When it comes to budgeting for a diaphragm pump, it's crucial to conduct a thorough cost vs. performance analysis. Diaphragm pumps can vary significantly in price, with high-quality industrial models costing between $1,000 to $5,000, while smaller, less durable versions may only cost a few hundred dollars. According to a recent market analysis report by ResearchAndMarkets, the global diaphragm pump market is expected to grow at a CAGR of 6.2% from 2021 to 2026, indicating a strong demand for reliable and efficient pumps. This growth suggests that investing in a high-performance model may yield long-term savings through reduced maintenance costs and increased operational efficiency.

Performance metrics such as flow rate, pressure capability, and material compatibility play a critical role in the overall cost-effectiveness of diaphragm pumps. For instance, selecting a pump that meets your specific viscosity and chemical compatibility needs can significantly reduce the risk of premature failure, which often leads to unplanned expenses. A study by the American Society of Mechanical Engineers highlighted that downtime caused by pump failures can result in losses upwards of $200,000 per hour for manufacturing industries. Therefore, while the initial investment in a quality diaphragm pump may be higher, the long-term benefits in terms of performance and operational stability make it a wise financial decision.

Related Posts

-

Troubleshooting Issues with Dual Diaphragm Pumps for Optimal Performance

-

What to Know About Diaphragm Vacuum Pumps: A Comprehensive Guide for Global Buyers

-

Challenges Encountered with Submersible Pumps in Industrial Applications

-

Unlocking Efficiency: The Advantages of 24V Water Pumps for Modern Applications

-

What is the Functionality of a Water Tank Pump in Modern Water Systems

-

Optimizing Efficiency: Essential Strategies for Chemical Transfer Pump Performance in Industry