Discovering the Advantages of Electric Diaphragm Pumps: Efficiency, Versatility, and Applications

In recent years, the focus on sustainable and efficient pumping solutions has led to a significant rise in the adoption of the electric diaphragm pump across various industries. According to a report by MarketsandMarkets, the global diaphragm pump market is projected to reach approximately $7.17 billion by 2025, growing at a CAGR of 6.2%. This growth can be attributed to the numerous advantages offered by electric diaphragm pumps, including their efficiency, versatility, and ability to handle a wide range of fluids. Characterized by their simple design and reliable performance, these pumps are increasingly favored for applications in sectors such as pharmaceuticals, food and beverage, and wastewater management. As businesses seek to optimize operations while reducing their environmental footprint, understanding the strengths of electric diaphragm pumps becomes crucial for making informed choices that align with sustainability goals.

Understanding the Working Principles of Electric Diaphragm Pumps

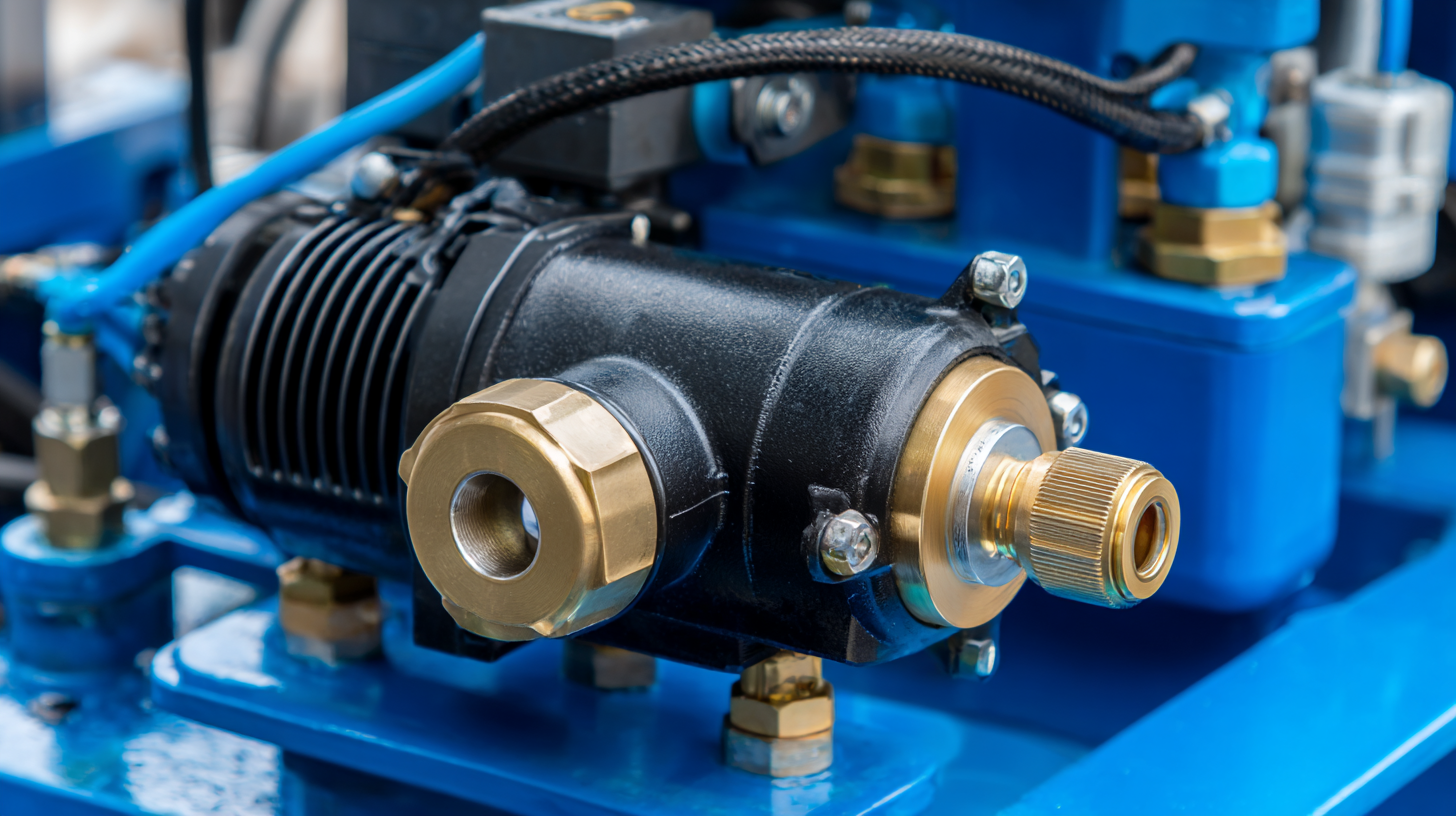

Electric diaphragm pumps are gaining traction in various industries due to their unique working principles, which provide both efficiency and versatility. Operating on the principle of positive displacement, these pumps use a flexible diaphragm that alternately moves up and down, creating a vacuum that draws fluid into the pump chamber. This mechanism allows for precise control over flow rates and is particularly advantageous for applications requiring gentle handling of fluids, such as in the food and beverage industry or in pharmaceuticals.

According to recent market analysis, the diaphragm pump market is expected to witness significant growth, with forecasts indicating a considerable increase in size and share by 2032. The report highlights the demand for both single-acting and double-acting diaphragm pumps driven by their wide-ranging applications, from chemical processing to wastewater management.

**Tips:** When selecting an electric diaphragm pump, consider the specific requirements of your application such as fluid type, viscosity, and required flow rate. Regular maintenance and monitoring can enhance pump efficiency and longevity, ensuring reliable performance in critical operations. Additionally, understanding the principles of operation can aid in troubleshooting and optimizing pump functionality for diverse applications.

Key Benefits of Using Electric Diaphragm Pumps in Various Industries

Electric diaphragm pumps have gained traction across various industries due to their inherent efficiency and versatility. As the diaphragm pump market is projected to grow from USD 6.27 billion in 2023 to an estimated USD 9.97 billion by 2032, it’s clear that businesses are recognizing these pumps' operational advantages. The energy-efficient design of electric diaphragm pumps allows for significant reductions in operational costs, particularly in processes involving high-viscosity fluids or hazardous chemicals.

In addition, these pumps are known for their impressive reliability and adaptability. The recent introduction of advanced electric diaphragm pump models enhances their application in sectors such as manufacturing and automotive. A key benefit includes their ability to function in chemically aggressive environments while maintaining low energy consumption. Furthermore, incorporating features like electronic leak detection and overpressure protection boosts safety and performance, making them an ideal choice for various industrial applications.

**Tips:** When considering electric diaphragm pumps, assess the specific requirements of your application to choose the right model. Ensure that the pump's specifications align with the viscosity and chemical nature of the fluids you intend to handle. Additionally, regular maintenance can prolong the life of these pumps and uphold their efficiency.

Advantages of Electric Diaphragm Pumps

Versatility: How Electric Diaphragm Pumps Adapt to Different Applications

Electric diaphragm pumps stand out for their versatility, making them suitable for various applications across numerous industries. According to a report from MarketsandMarkets, the global diaphragm pump market is projected to grow at a CAGR of 4.7% from 2021 to 2026, largely driven by the increasing demand for reliable and efficient fluid transfer solutions. These pumps are capable of handling a wide range of fluids, from water and slurries to highly viscous or corrosive substances, thanks to their robust design and flexible configurations.

Electric diaphragm pumps stand out for their versatility, making them suitable for various applications across numerous industries. According to a report from MarketsandMarkets, the global diaphragm pump market is projected to grow at a CAGR of 4.7% from 2021 to 2026, largely driven by the increasing demand for reliable and efficient fluid transfer solutions. These pumps are capable of handling a wide range of fluids, from water and slurries to highly viscous or corrosive substances, thanks to their robust design and flexible configurations.

One significant advantage of electric diaphragm pumps is their ability to adapt to different operational conditions. Whether in chemical processing, food and beverage, or wastewater management, electric diaphragm pumps can be customized for specific pumping requirements. For instance, they can operate in tough environments where traditional pumps might fail, maintaining efficiency and minimizing downtime.

Tips: When selecting an electric diaphragm pump, consider the specific fluid characteristics, temperature range, and necessary flow rates. Additionally, always ensure compatibility with the materials used in the pump to enhance durability and performance. Investing in a pump with variable speed options can further increase operational flexibility and energy efficiency, making it an invaluable asset in diverse applications.

Maximizing Efficiency: Tips for Optimal Performance of Electric Diaphragm Pumps

Electric diaphragm pumps are known for their efficiency and versatility, making them an ideal choice for various applications. To maximize the performance of these pumps, it is essential to focus on several best practices.

First, ensuring proper installation is crucial. This includes selecting the appropriate size and type of pump for your specific needs, as well as following the manufacturer's guidelines for setup. A well-installed pump minimizes wear and tear, enhancing its lifespan and efficiency.

In addition to installation, regular maintenance plays a vital role in maintaining optimal performance. Routine checks of the diaphragm, valves, and seals can prevent leaks and ensure consistent operation. Keeping the pump clean and free of debris will also help maintain its efficiency.

Furthermore, monitoring operational parameters such as pressure and flow rate allows for early identification of potential issues, enabling timely intervention. By prioritizing these tips, users can significantly enhance the efficiency and reliability of their electric diaphragm pumps, ultimately leading to improved productivity in various applications.

Comparative Analysis: Electric Diaphragm Pumps vs. Traditional Pumping Solutions

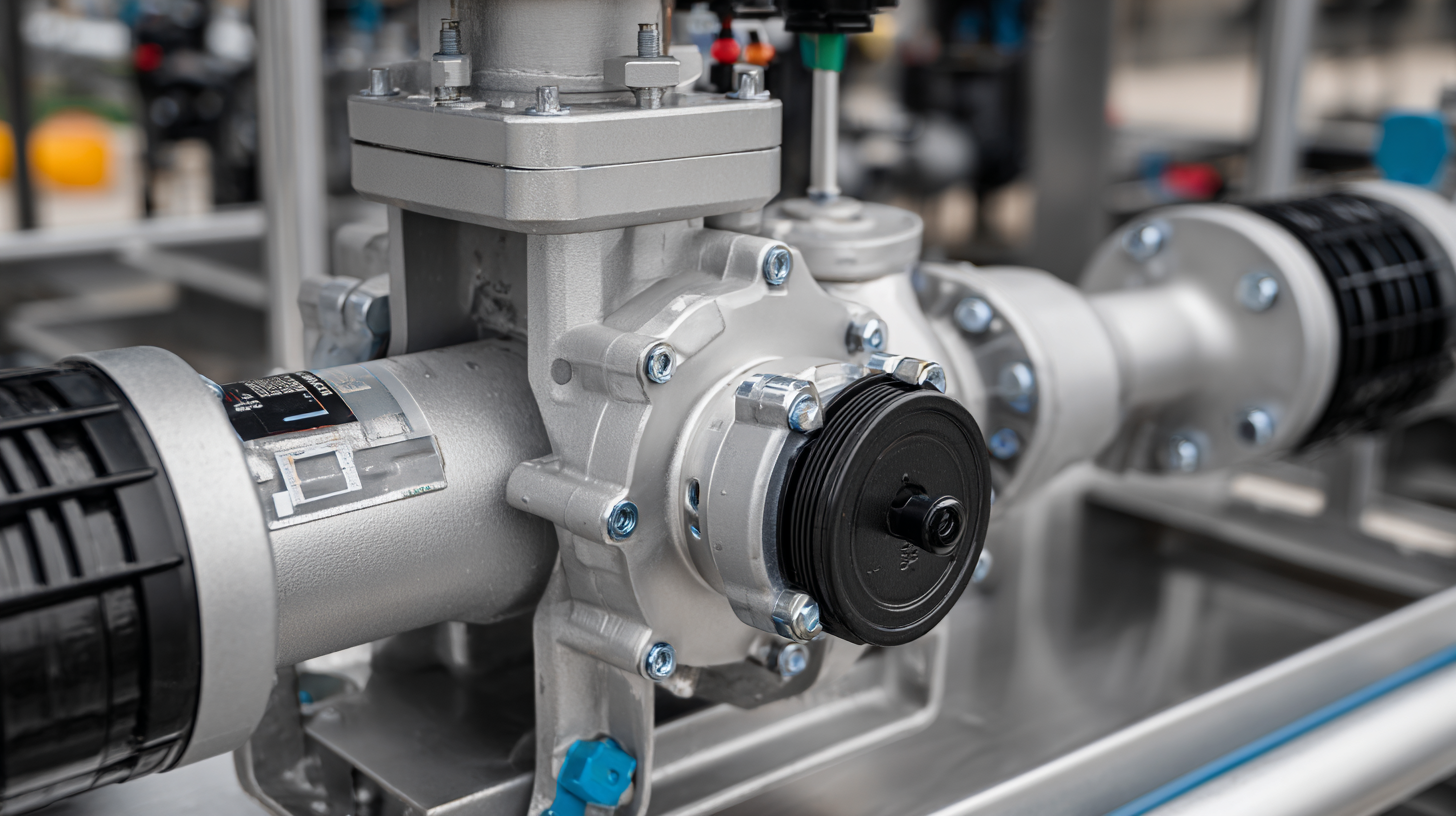

Electric diaphragm pumps offer notable advantages over traditional pumping solutions, particularly in terms of efficiency and versatility. Unlike conventional pumps that often rely on mechanical parts that can wear down and require maintenance, electric diaphragm pumps utilize a diaphragm to create a sealed chamber, drastically reducing wear and enhancing operational longevity. This technology enables them to handle a wide range of fluids, including corrosive and viscous materials, while maintaining a consistent flow rate. The efficiency of electric diaphragm pumps minimizes energy consumption, which is especially crucial in applications where energy savings translate directly to reduced operational costs.

In terms of applications, electric diaphragm pumps are increasingly relevant in sectors such as renewable energy and advanced automotive technology, including braking systems in electric vehicles. As the demand for more efficient braking systems grows, the reliability and precision offered by diaphragm pumps make them an attractive option. Additionally, the development of energy storage technologies, like next-generation flow batteries, highlights the critical need for effective fluid management systems. Electric diaphragm pumps can play a vital role in these systems, ensuring optimized flow and improved performance, thereby bridging the gap between traditional mechanical pumping solutions and modern energy requirements.

Related Posts

-

Exploring the Impact of the Small Vacuum Pump Industry at the 2025 China Import and Export Fair

-

Exploring the Efficiency of Electric Transfer Pumps: A Detailed Study on Flow Rates and Energy Consumption Trends

-

Challenges Encountered with Submersible Pumps in Industrial Applications

-

Comprehensive Guide to Choosing the Right High Pressure Diaphragm Pump for Your Needs

-

Unleashing Efficiency: How High-Pressure Water Pumps Transform Agricultural Irrigation Systems

-

Exploring the Impact of 24v Water Pump Innovations at the 138th China Import and Export Fair 2025