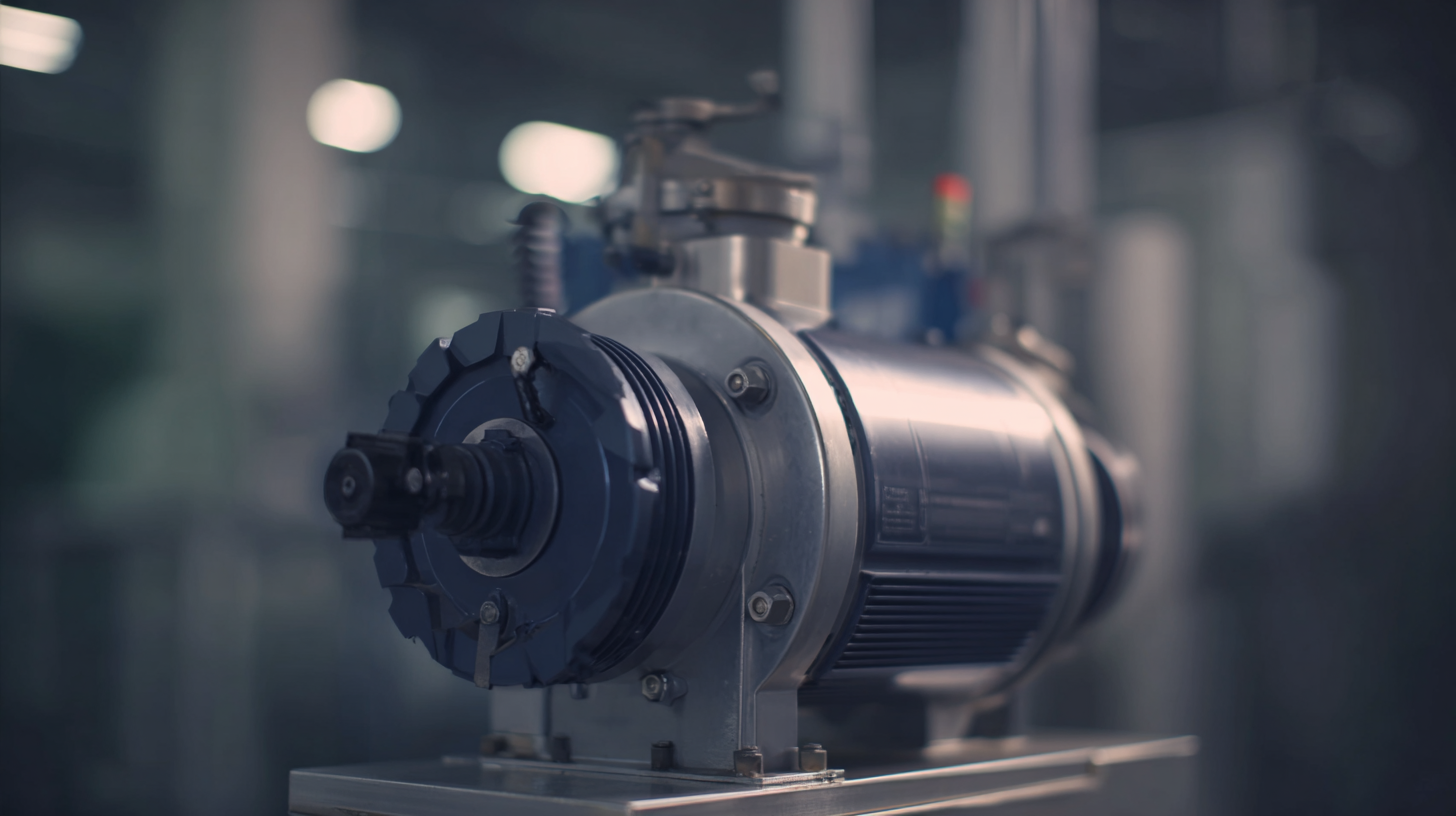

Exploring the Efficiency of Electric Transfer Pumps: A Detailed Study on Flow Rates and Energy Consumption Trends

Electric transfer pumps have become integral to various industries, particularly in the context of enhancing operational efficiency and sustainability. As noted in the Annual Report on Energy Efficiency in Pumping Systems, electric transfer pumps can achieve operational efficiency rates of up to 85%, significantly reducing energy consumption compared to traditional mechanical pumps. This efficiency translates to considerable cost savings and a lowered carbon footprint, aligning with global sustainability goals.

Recent studies indicate that the global market for electric transfer pumps is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2021 to 2027, driven by increasing demand for energy-efficient solutions in water management, industrial processes, and agriculture. In this detailed study, we will explore the flow rates and energy consumption trends associated with electric transfer pumps, providing insights that can drive better decision-making in their selection and application across various sectors.

Evaluating the Role of Flow Rates in Electric Transfer Pump Efficiency Metrics

The efficiency of electric transfer pumps is intricately linked to their flow rates, a crucial metric for evaluating overall performance. High flow rates typically correlate with enhanced efficiency, as they indicate the ability of a pump to move larger volumes of liquid with reduced energy consumption. This relationship underscores the importance of optimizing flow rates in the design and operational strategies of electric transfer pumps.

By analyzing variations in flow rates, manufacturers can identify ideal operating conditions that maximize pump efficiency, thereby improving energy utilization within various applications.

Moreover, trends in energy consumption associated with electric transfer pumps reveal significant insights into their operational efficiency. As industries increasingly seek to minimize energy costs, understanding the dynamics of flow rates can help establish guidelines for best practices in pump utilization. The integration of advanced monitoring technologies allows for real-time analysis, enabling operators to adjust flow rates dynamically in response to varying demands. This adaptation not only enhances efficiency but also contributes to sustainability efforts in sectors reliant on electric transfer pumps, aligning with broader goals of reducing energy waste and promoting environmentally friendly practices.

Comparative Analysis of Energy Consumption Across Different Electric Transfer Pump Models

The North American utility pump market is poised for significant growth, projected to reach a value of $2.14 billion in 2024 and expected to expand to $2.23 billion in 2025, ultimately hitting $3.04 billion by 2032. This surge highlights the increasing reliance on electric transfer pumps across various sectors, emphasizing the need for efficiency and energy consumption awareness.

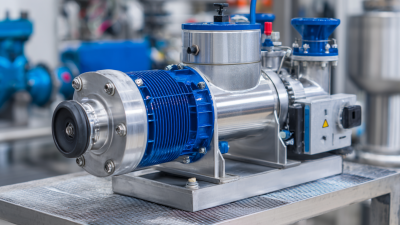

A comparative analysis of energy consumption across different electric transfer pump models reveals marked variations in flow rates and operational efficiency. Recent studies indicate that while some models boast higher flow rates, they may consume substantially more energy, negating potential efficiency benefits. Understanding the energy consumption trends of these pumps is vital for utility companies aiming to optimize their operations and reduce overall costs. With a growing emphasis on sustainability and energy efficiency, investing in the right electric transfer pump models can lead to significant long-term savings and improved environmental impact.

Exploring the Efficiency of Electric Transfer Pumps: A Detailed Study on Flow Rates and Energy Consumption Trends

| Pump Model | Flow Rate (L/min) | Energy Consumption (kWh) | Efficiency (%) |

|---|---|---|---|

| Model A | 200 | 1.5 | 85 |

| Model B | 150 | 1.2 | 80 |

| Model C | 250 | 1.8 | 90 |

| Model D | 180 | 1.3 | 82 |

| Model E | 220 | 1.6 | 87 |

Industry Standards: Optimal Flow Rates for Maximum Efficiency in Electric Pumps

The performance of electric transfer pumps is heavily influenced by specific industry standards that dictate optimal flow rates. These standards are fundamentally designed to enhance efficiency, reduce operational costs, and extend the life span of the equipment. For most applications, electric pumps should operate within a designated flow rate range that balances the demands of the system with energy consumption levels. By adhering to these recommended flow rates, the pumps can achieve their peak performance while minimizing energy wastage.

Understanding these optimal flow rates is crucial for industries that rely on electric transfer pumps for various applications. For instance, maintaining flow rates that are too low can lead to issues such as cavitation, while excessively high flow rates might cause mechanical wear and increase energy consumption disproportionately. Thus, industry professionals must analyze the specific requirements of their operational environment and adjust the pumps accordingly. By implementing such standards, facilities can not only ensure efficient pump operation but also significantly reduce their overall energy consumption and operational costs.

Flow Rates and Energy Consumption Trends of Electric Transfer Pumps

Case Studies: Real-World Performance Data on Electric Transfer Pump Efficiency

In assessing the efficiency of electric transfer pumps, real-world performance data plays a crucial role in understanding their operational metrics. According to a recent report by the American Society of Mechanical Engineers (ASME), electric transfer pumps typically demonstrate flow rates ranging from 100 to 500 liters per minute. In one case study, a municipal water treatment facility implemented electric pumps that achieved a consistent flow rate of 450 liters per minute while consuming only 1.2 kWh per 1000 liters processed. Such findings affirm not only the pumps' effectiveness in terms of flow but also their energy efficiency, which is increasingly vital in reducing operational costs.

Moreover, further analysis by the Hydraulic Institute highlighted that electric transfer pumps can exhibit energy consumption trends that vary significantly based on application. For instance, in agricultural settings, where water flow demands can fluctuate dramatically, a study indicated that variable-speed pumps can reduce energy usage by up to 30% compared to traditional fixed-speed models. These insights underscore the importance of evaluating specific case studies to glean accurate data on pump performance, guiding future innovations and enhancements in pump technology to promote sustainability across various industries.

Future Innovations: Trends in Energy Efficiency for Electric Transfer Pump Technology

The evolution of electric transfer pump technology has paved the way for significant advancements in energy efficiency. Recent innovations in this field focus on optimizing design and materials, resulting in pumps that require less energy while maintaining high flow rates. By leveraging advanced motor technologies and intelligent control systems, manufacturers are now able to produce pumps that not only minimize energy consumption but also enhance operational reliability. Such improvements are crucial in various industries, from agriculture to municipal water supply, where efficiency can lead to substantial cost savings and reduced environmental impact.

In addition to smarter engineering, future trends also highlight the integration of renewable energy sources into electric transfer pump systems. Solar-powered pumps, for instance, are gaining traction in remote applications where traditional power sources are limited. The combination of energy-efficient pumps with renewable technologies not only promotes sustainability but also addresses the growing demand for decentralized energy solutions. As the industry continues to innovate, understanding these trends will be essential for stakeholders aiming to adopt cutting-edge electric transfer pump systems that support both economic viability and environmental stewardship.

Related Posts

-

7 Expert Tips to Choose the Best Fountain Pump for Your Garden Water Feature

-

Understanding the Importance of Bleach Pumps in Industrial Cleaning Processes

-

Comprehensive Guide to Choosing the Right High Pressure Diaphragm Pump for Your Needs

-

How to Choose the Right Chemical Transfer Pump for Your Industrial Needs

-

What to Know About Diaphragm Vacuum Pumps: A Comprehensive Guide for Global Buyers

-

How to Choose the Right 24v Water Pump for Your Irrigation Needs