Understanding the Benefits of High Pressure Pumps in Industrial Applications

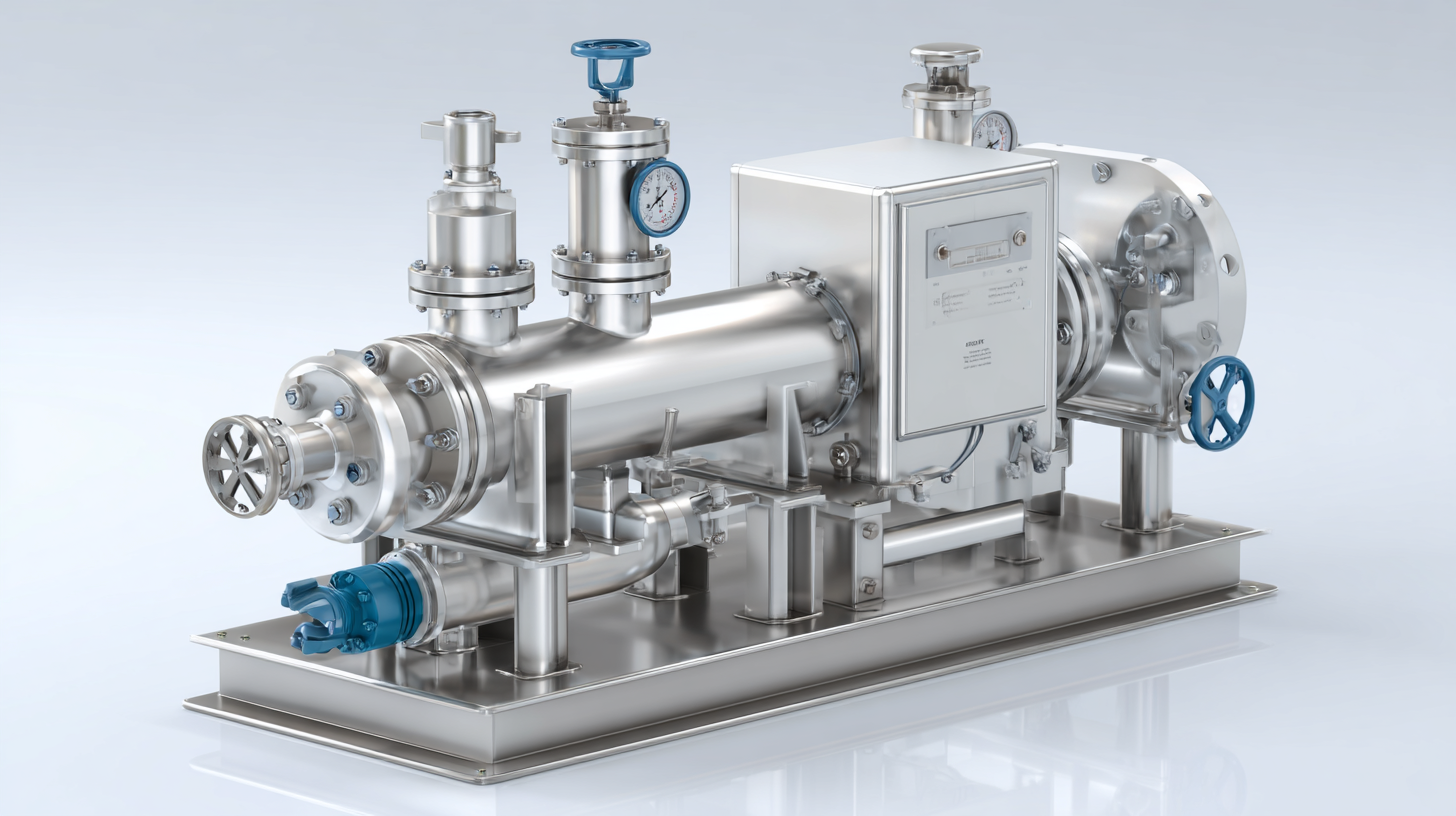

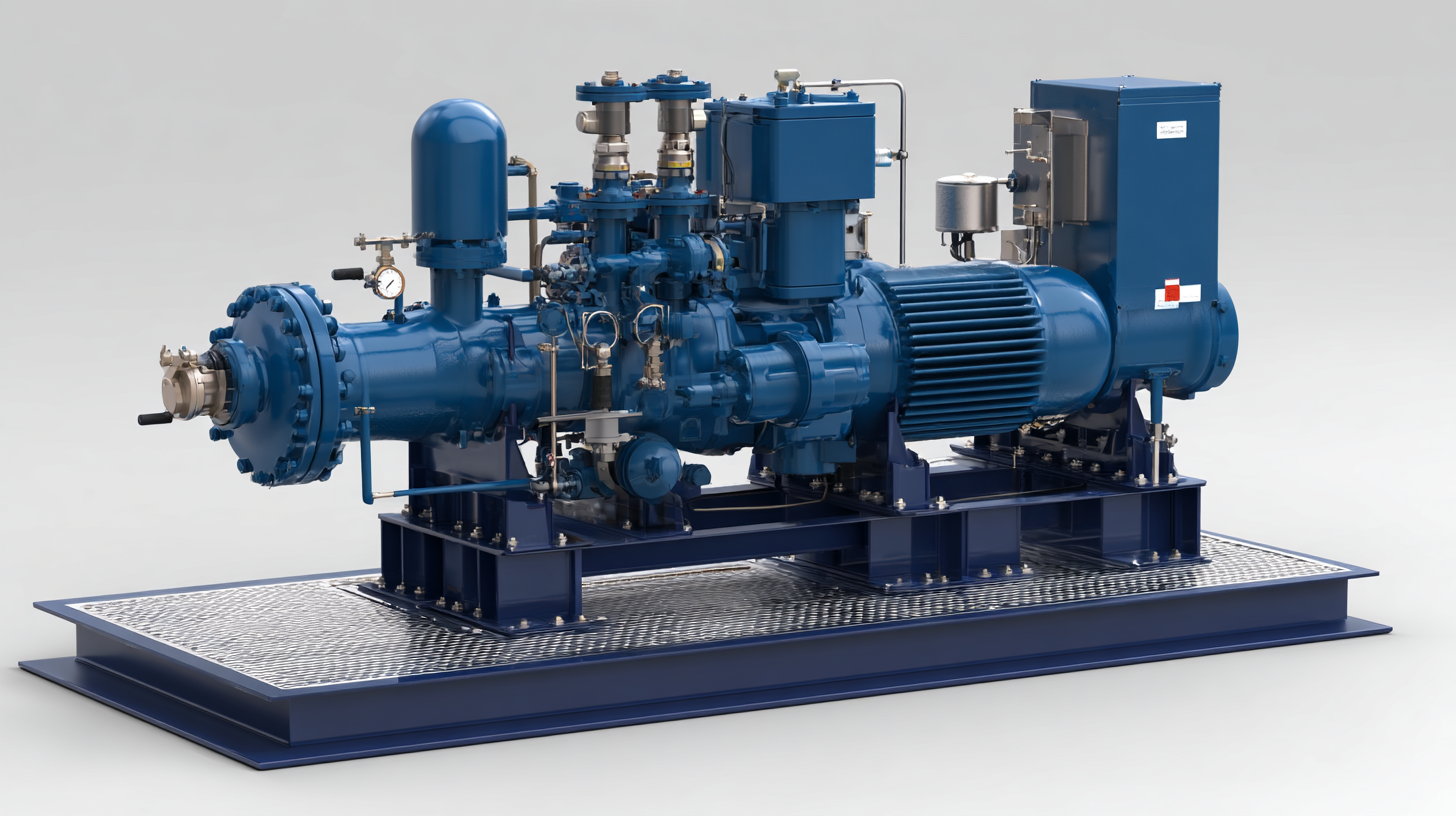

In the ever-evolving landscape of industrial applications, the significance of high pressure pumps cannot be overstated. These powerful devices play a crucial role in a diverse range of operations, from water treatment and chemical processing to oil and gas extraction. Their ability to generate and maintain elevated pressure levels makes them indispensable for tasks that require the efficient movement and spraying of fluids. As industries increasingly prioritize operational efficiency and reduced downtime, understanding the benefits of high pressure pumps has become essential for maximizing productivity and minimizing costs.

High pressure pumps offer numerous advantages that enhance performance and reliability across various sectors. Their design allows for consistent flow rates and the ability to handle a wide array of fluids, including corrosive substances and slurries. Furthermore, advancements in technology have led to more durable and energy-efficient pumps, which not only prolong service life but also contribute to sustainability goals. In this article, we will explore the "Top 5" benefits of high pressure pumps in industrial applications, highlighting how these essential tools streamline processes and drive innovation in today’s competitive market.

How to Select the Right High Pressure Pump for Your Industrial Needs

When selecting the right high pressure pump for industrial needs, it is crucial to consider various technical specifications and application requirements. High pressure pumps come in diverse designs, each tailored to specific tasks, from material transfer to pressure washing. According to industry reports, the global market for high pressure pumps is projected to reach USD 5.1 billion by 2027, growing at a CAGR of 6.8% from 2020 to 2027, driven by advancements in manufacturing processes and increasing demand from sectors like construction and mining.

Factors such as pressure rating, fluid compatibility, and efficiency are essential when making a selection. For instance, a high-pressure pump with a capacity of 120W, as showcased in recent innovations, demonstrates the significant improvements in efficiency and effectiveness for applications like rapid charge solutions. Furthermore, when evaluating high pressure pumps, understanding the installation requirements and maintenance needs can lead to better performance and longevity of the equipment. As industrial operations continue to evolve, selecting the right pump can enhance productivity and ensure safety across various applications.

Understanding the Benefits of High Pressure Pumps in Industrial Applications - How to Select the Right High Pressure Pump for Your Industrial Needs

| Pump Type | Pressure Range (psi) | Flow Rate (GPM) | Application | Efficiency Rating |

|---|---|---|---|---|

| Piston Pump | 1500 - 5000 | 0.5 - 15 | Water Jet Cutting | 85% |

| Diaphragm Pump | 100 - 2000 | 1 - 10 | Chemical Transfer | 90% |

| Gear Pump | 500 - 3000 | 0.5 - 50 | Hydraulic Systems | 80% |

| Centrifugal Pump | 100 - 1500 | 5 - 500 | Water Supply | 75% |

| Peristaltic Pump | 50 - 1500 | 0.1 - 120 | Food Processing | 88% |

How to Optimize High Pressure Pump Performance in Various Applications

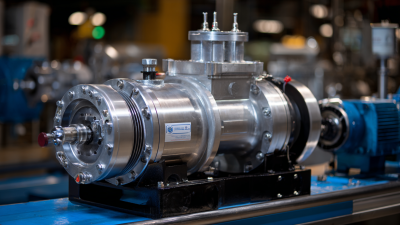

High-pressure pumps are essential components in various industrial applications, enabling efficient fluid transfer and enhancing operational effectiveness. To optimize high-pressure pump performance, it is crucial to understand the specific requirements of each application. Factors such as flow rate, pressure needs, and fluid viscosity should be accurately assessed to select the right pump type and configuration. Regular maintenance and the use of quality materials are also key in ensuring longevity and peak efficiency.

In addition, employing advanced monitoring and control systems can significantly enhance the operation of high-pressure pumps. Implementing technologies such as real-time performance tracking allows for timely adjustments and troubleshooting, ultimately reducing downtime and operational costs. As industries continue to evolve and expand, the demand for reliable high-pressure pumps is projected to grow, with the global market forecasted to steadily increase from $159.04 million in 2025 to $121.72 million by 2033, reflecting a compound annual growth rate of 3.4%. This growth underscores the importance of continuous improvement in pump performance to meet the increasing demands of industrial sectors.

Understanding the Benefits of High Pressure Pumps in Industrial Applications

How to Maintain High Pressure Pumps for Maximum Efficiency and Longevity

Proper maintenance of high-pressure pumps is crucial for ensuring maximum efficiency and longevity in industrial applications. Regular inspections and timely servicing can significantly enhance the performance of these pumps. Key maintenance practices include checking for any signs of wear or damage, ensuring seals and gaskets are intact, and monitoring fluid levels and conditions. A proactive maintenance approach helps to avoid unexpected downtimes and costly repairs, ultimately leading to improved operational efficiency and reduced overall costs.

As the hydraulic pump market is projected to grow, with specific segments such as high-pressure piston pumps also on the rise, it becomes increasingly important for industries to prioritize maintenance strategies. With a compound annual growth rate of 3.4% anticipated for high-pressure piston pumps through 2033, industries must invest in maintenance protocols that not only prolong the lifespan of these pumps but also enhance their output capability. Emphasizing routine maintenance can maximize the return on investment in high-pressure pump technology, making it a vital component of industrial operations.

How to Troubleshoot Common Issues with High Pressure Pumps in Industry

Troubleshooting high pressure pumps in industrial applications is essential for maintaining efficiency and preventing costly downtime. Common issues include irregular pressure fluctuations, abnormal noises, and overheating. When experiencing pressure inconsistencies, it’s crucial to check for blockages in the inlet and outlet lines. These obstructions can lead to reduced flow and ineffective operation. Additionally, verifying that all seals and fittings are secure can help prevent leaks, which might compromise pump performance.

Troubleshooting high pressure pumps in industrial applications is essential for maintaining efficiency and preventing costly downtime. Common issues include irregular pressure fluctuations, abnormal noises, and overheating. When experiencing pressure inconsistencies, it’s crucial to check for blockages in the inlet and outlet lines. These obstructions can lead to reduced flow and ineffective operation. Additionally, verifying that all seals and fittings are secure can help prevent leaks, which might compromise pump performance.

Another frequent problem is unusual noises, which can indicate issues like cavitation or mechanical wear. To address cavitation, operators should ensure that the pump is not operating outside its required NPSH (Net Positive Suction Head) limits. Adjustments to the system's suction conditions may be necessary. If noise persists, inspecting the bearings and impellers for wear can help identify mechanical failures that require repair or replacement. Regular maintenance practices, such as lubrication and inspection of internal components, can significantly reduce the likelihood of such issues, ensuring high pressure pumps operate smoothly and reliably in industrial settings.

How to Integrate High Pressure Pumps into Your Existing System Effectively

Integrating high pressure pumps into existing industrial systems requires careful planning and execution to maximize efficiency and performance. According to a report by the National Association of Manufacturers, over 30% of industrial processes can benefit from optimized pumping solutions, which highlight the significance of high pressure systems. When introducing these pumps, it's critical to evaluate the compatibility with current hydraulic designs and pressure requirements. This ensures that the new system operates under optimal conditions, reducing the risk of mechanical failure and downtime.

To achieve effective integration, industries should conduct a thorough assessment of flow rates and operational parameters. The Hydraulic Institute's latest guidelines suggest that proper alignment and installation can increase pump life by up to 25%. Additionally, incorporating automated control systems can enhance operational efficiency by adjusting pump performance in real time based on demand. By leveraging data from performance monitoring tools, companies can make informed decisions about maintenance schedules and system upgrades, ultimately leading to significant cost savings and improved productivity.

Related Posts

-

How to Optimize Efficiency with High Pressure Pump Selection

-

11 Best Soft Wash Pump Solutions for Effective Cleaning

-

7 Essential Tips for Choosing the Best Electric Water Pump for Your Needs

-

Unleashing Efficiency: How High-Pressure Water Pumps Transform Agricultural Irrigation Systems

-

7 Expert Tips to Choose the Right Industrial Pumps for Your Business Success

-

How to Choose the Right 24v Water Pump for Your Irrigation Needs